- Home

- Plastic Gear Injection Moulding

Top-notch Plastic Gear Injection Moulding Manufacturer in China

Introducing our latest innovation in the field of plastic gear injection moulding, brought to you by Shenzhen RCT MFG Co., Ltd. As a leading manufacturer, supplier, and factory in the industry, we take pride in delivering top-quality products at affordable prices.

Our plastic gear injection moulding process ensures precision and durability, resulting in gears that can withstand even the most demanding applications. By utilizing state-of-the-art technology and the expertise of our skilled team, we produce gears that are resistant to wear, corrosion, and extreme temperatures.

At Shenzhen RCT MFG Co., Ltd., we understand the importance of cost-effectiveness without compromising on quality. Our cheap plastic gear injection moulding solutions cater to both small-scale and large-scale production requirements, making them suitable for various industries.

Whether you need gears for automotive, electronics, or industrial applications, we are committed to providing you with unmatched products and services. Partner with Shenzhen RCT MFG Co., Ltd. and experience the difference of working with a reputable company that prioritizes customer satisfaction. Contact us today to discuss your plastic gear injection moulding needs.

Shenzhen RCT MFG CO., LTD

Company News

Related News

Precision anodized 7075 Aluminium Machined Wheels for Automative

Shop our line of precision anodized 7075 aluminium machined wheels for the automotive industry. As a factory, we offer quality products at competitive prices.

New RCT CNC Machining ABS plastic parts prototype for product development

Get high-quality ABS plastic parts prototypes for product development with our top-notch RCT CNC machining services. We are a leading factory offering expert manufacturing solutions.

Shenzhen Die Casting Factory Custom A380 ADC12 Die Cast Part Aluminum Die Casting

Welcome to our Shenzhen Die Casting Factory specializing in custom A380 ADC12 die cast aluminum parts. We are a trusted manufacturer with excellent quality and competitive prices.

CNC Turning and Milling Delrin/POM parts

Looking for high-quality Delrin/POM parts? Our factory specializes in CNC turning and milling services. Get precision parts with quick turnaround times.

Customized High Precision CNC Machining Parts for Aquatic Products Testing Equipmen

Shop our factory's customized high precision CNC machining parts for aquatic products testing equipment. Durable, accurate and reliable. Explore now!

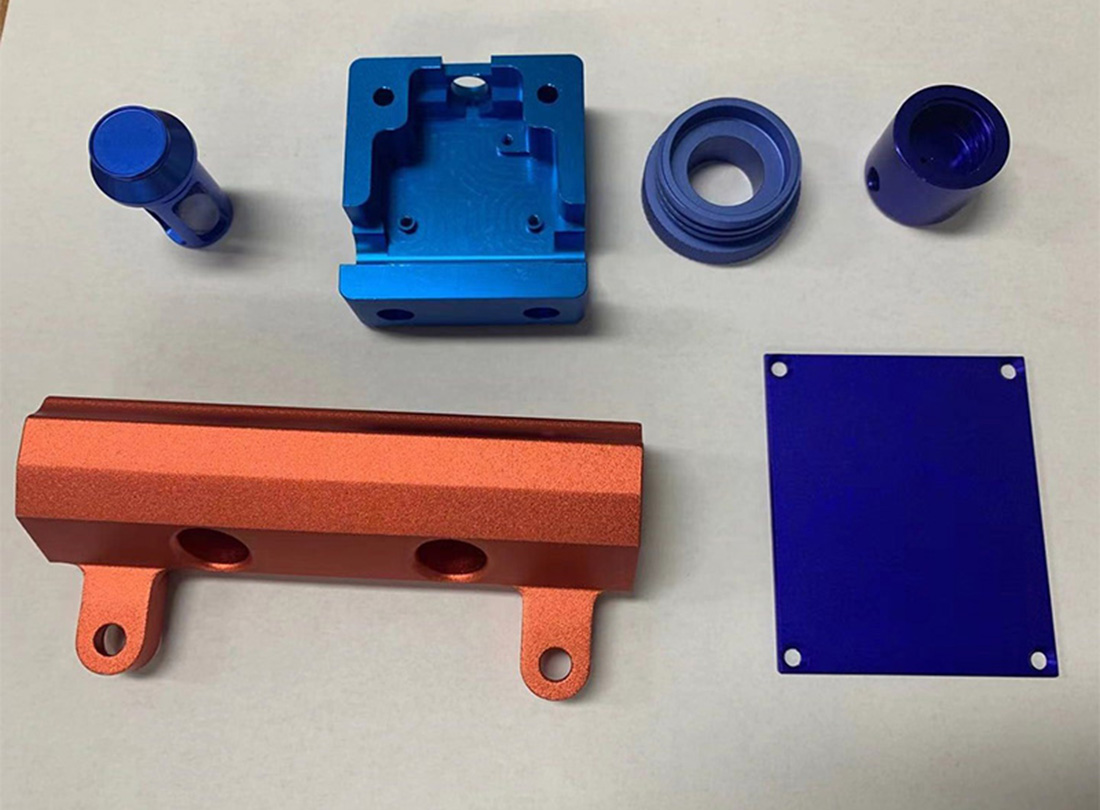

Aluminum 6061 CNC machining Precision Parts for Electronics

Buy high-quality Aluminum 6061 CNC machining precision parts for electronics manufacturing. We are a reliable factory offering superior products at competitive prices.

Custom Aluminium enclosure sheet metal fabrication

Get top-quality custom aluminium enclosure sheet metal fabrication from our factory. We specialize in precision manufacturing for various industries. Contact us today!

Precision biodegradable PLA Bioplastic Injection Molding

Looking for biodegradable PLA injection molding products? Our factory offers precision biodegradable PLA bioplastics for eco-friendly solutions. Contact us now!

CNC Machining of stainless steel housigg for the Gas Compression Equipment Industry

Get top-quality stainless steel housings for the Gas Compression Equipment Industry with our CNC Machining services. We are a trusted factory committed to precision and efficiency.

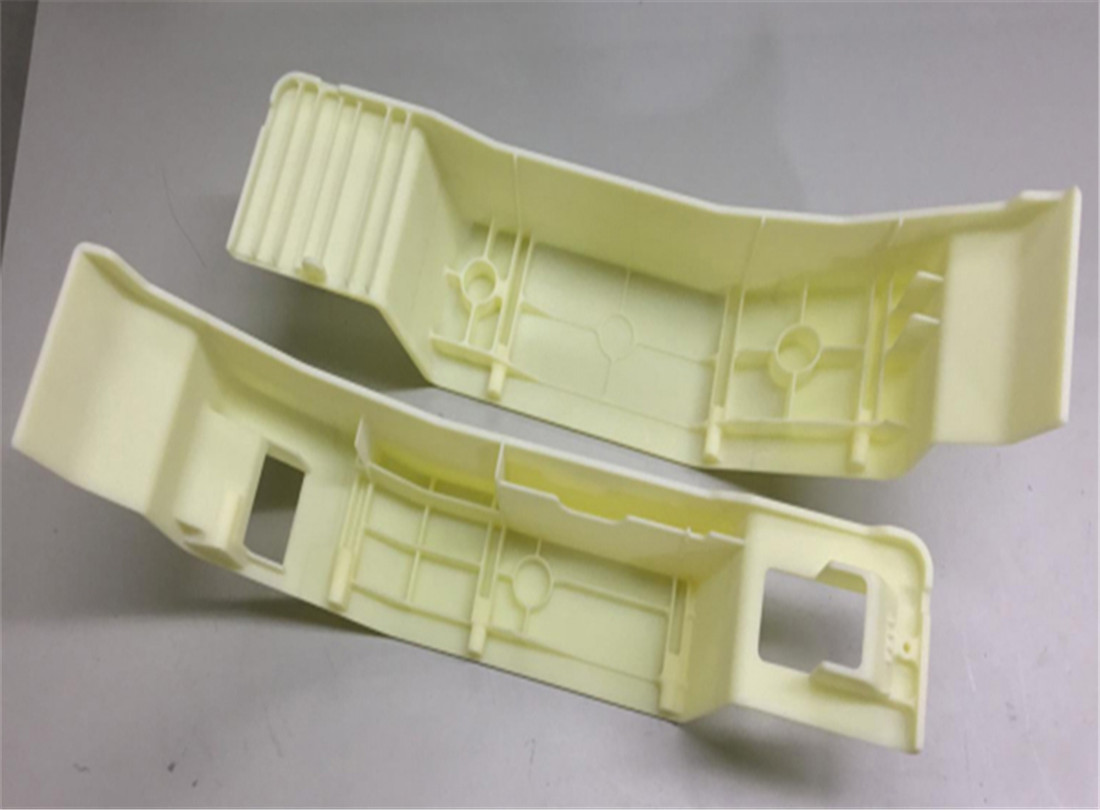

Low Volume Production Automative spare parts Urethane Casting

Factory specializing in low volume production of automotive spare parts through Urethane Casting. Trust us for high-quality, custom-made solutions.

Automotive Plastic Parts injection molding

Find high-quality automotive plastic parts through our injection molding factory. Our precision manufacturing ensures durable and reliable products.

CNC Milling of High Precision Aluminum Machined Parts for the Process Fluid Circulation Industry

Looking for high precision aluminum machined parts for the process fluid circulation industry? We are a factory specializing in CNC milling to meet your needs.

Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts

Shop our high-quality Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts at our factory. Find precise components for efficient machining operations.

Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts

Experience premium quality with our Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts. As a factory, we assure top-notch craftsmanship and tailored solutions. Shop now!

High precision injection molds industrial machine injection mould

Choose our high precision industrial machine injection molds for superior product quality. As a factory, we specialize in offering reliable and efficient injection molding solutions. Contact us now!

- Leading Manufacturer of Plastic Gear Injection Moulding in China

- Reviews

- Related Videos

Introducing our revolutionary Plastic Gear Injection Moulding technology, designed to transform the way gears are manufactured. With precision, efficiency, and durability at its core, our innovative solution is set to revolutionize the industry. Our state-of-the-art Plastic Gear Injection Moulding process guarantees precise manufacturing, ensuring consistent gear quality and reliability. The advanced technology utilized in our injection moulding process allows for complex gear designs and tight tolerances, meeting the highest industry standards. We leverage cutting-edge machinery and materials to deliver gears with exceptional strength and resistance, capable of withstanding even the most demanding applications. One key advantage of our Plastic Gear Injection Moulding is its unparalleled efficiency. With automated processes and high-speed manufacturing capabilities, we are able to produce large quantities of gears in a significantly shorter time frame compared to traditional manufacturing methods, thereby reducing production costs and increasing overall productivity. In addition, our plastic gears offer superior performance when compared to conventional metal gears. Thanks to their lightweight nature and excellent wear resistance, they minimize friction and noise, leading to smoother and more efficient machinery operation. Furthermore, our plastic gears are resistant to corrosion and chemicals, making them suitable for a wide range of industries, including automotive, aerospace, and consumer electronics. When it comes to quality, precision, and innovation in gear manufacturing, our Plastic Gear Injection Moulding technology stands out above the rest. Experience the future of gears with our game-changing solution, delivering extraordinary performance and manufacturing efficiency for your business.

I recently purchased a plastic gear injection moulding product and I must say, it exceeded my expectations. The quality of the gears is exceptional and the precision in their design is evident. The injection moulding technique ensures durability and strength, making these gears perfect for various applications. I was particularly impressed by the smooth operation and minimal friction offered by these gears. The product is also lightweight, which makes it convenient for usage in different projects. Overall, the plastic gear injection moulding product is a reliable and efficient solution for any gear-related needs.

I recently purchased a plastic gear that was made using injection molding technology, and I must say, I am highly impressed with its quality and functionality. The gear is sturdy and well-designed, ensuring smooth and efficient operation. The injection molding process has resulted in precise detailing, allowing the gear to fit perfectly into my machinery. I appreciate the durability of this product, as it shows no signs of wear even after consistent usage. The material used for molding is of high quality, making the gear resistant to external factors such as heat and moisture. Overall, I am extremely satisfied with this plastic gear and highly recommend it for any industrial applications.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours