- Home

- Soft Tooling Injection Molding

Soft Tooling Injection Molding Manufacturer in China: High-Quality and Customized Solutions

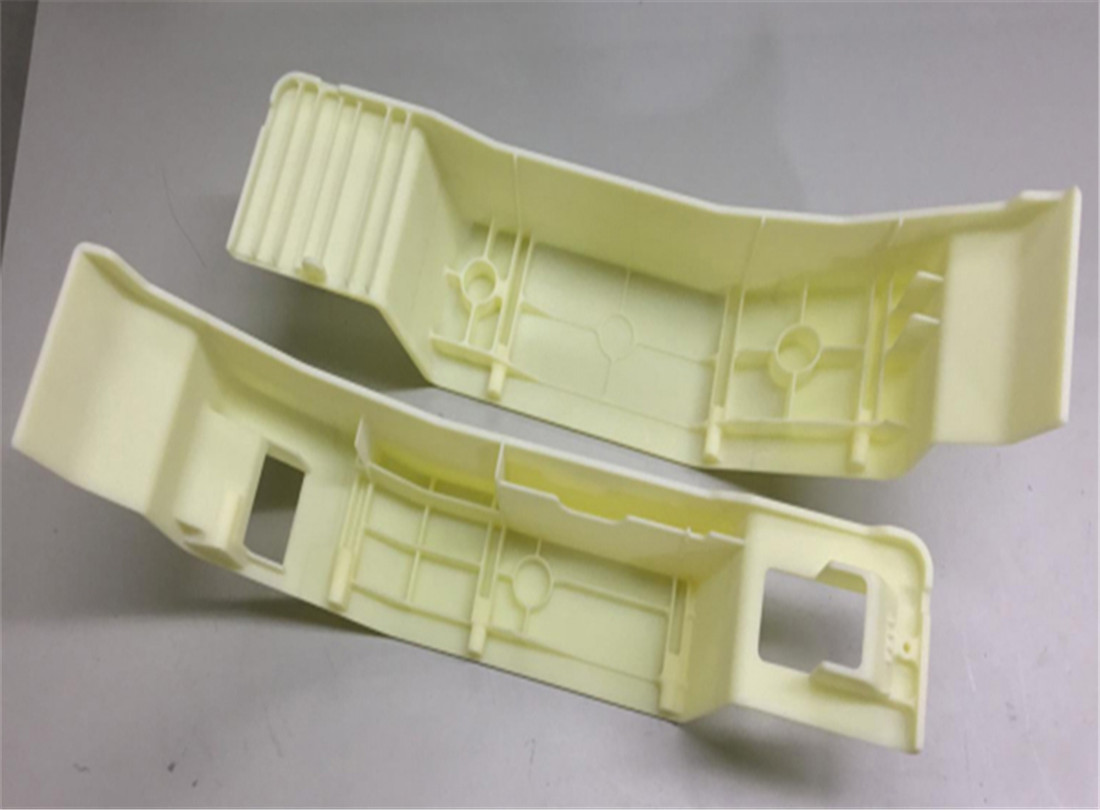

Introducing Soft Tooling Injection Molding, an innovative manufacturing process that offers cost-effective solutions for product development and production. Shenzhen RCT MFG Co., Ltd., a renowned manufacturer, supplier, and factory in the industry, takes pride in offering this cutting-edge technology at an affordable price.

Soft Tooling Injection Molding revolutionizes traditional manufacturing methods by providing a cost-effective alternative to hard tooling. This enables businesses of all sizes, including startups and small enterprises, to bring their ideas to life without breaking the bank. Our advanced soft tooling process ensures rapid prototyping and short lead times, allowing for quick iterations and reduced time to market.

With Soft Tooling Injection Molding, you can expect high-quality, precise, and durable products. Our skilled team of experts ensures flawless execution and adherence to strict quality standards throughout the entire manufacturing process. Whether you require small-scale production or large-volume manufacturing, Shenzhen RCT MFG Co., Ltd. has the capability to meet your specific requirements.

Choose Shenzhen RCT MFG Co., Ltd. for your soft tooling injection molding needs and benefit from our extensive experience, dedication to excellence, and commitment to delivering exceptional results. Experience the convenience and cost-effectiveness of Soft Tooling Injection Molding today, and witness your product ideas become a reality like never before.

Shenzhen RCT MFG CO., LTD

Company News

Related News

High precision injection molds industrial machine injection mould

Choose our high precision industrial machine injection molds for superior product quality. As a factory, we specialize in offering reliable and efficient injection molding solutions. Contact us now!

Customized High Precision CNC Machining Parts for Aquatic Products Testing Equipmen

Shop our factory's customized high precision CNC machining parts for aquatic products testing equipment. Durable, accurate and reliable. Explore now!

Precision anodized 7075 Aluminium Machined Wheels for Automative

Shop our line of precision anodized 7075 aluminium machined wheels for the automotive industry. As a factory, we offer quality products at competitive prices.

Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts

Shop our high-quality Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts at our factory. Find precise components for efficient machining operations.

Automotive Plastic Parts injection molding

Find high-quality automotive plastic parts through our injection molding factory. Our precision manufacturing ensures durable and reliable products.

CNC Machining of stainless steel housigg for the Gas Compression Equipment Industry

Get top-quality stainless steel housings for the Gas Compression Equipment Industry with our CNC Machining services. We are a trusted factory committed to precision and efficiency.

Precision biodegradable PLA Bioplastic Injection Molding

Looking for biodegradable PLA injection molding products? Our factory offers precision biodegradable PLA bioplastics for eco-friendly solutions. Contact us now!

Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts

Experience premium quality with our Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts. As a factory, we assure top-notch craftsmanship and tailored solutions. Shop now!

CNC Turning and Milling Delrin/POM parts

Looking for high-quality Delrin/POM parts? Our factory specializes in CNC turning and milling services. Get precision parts with quick turnaround times.

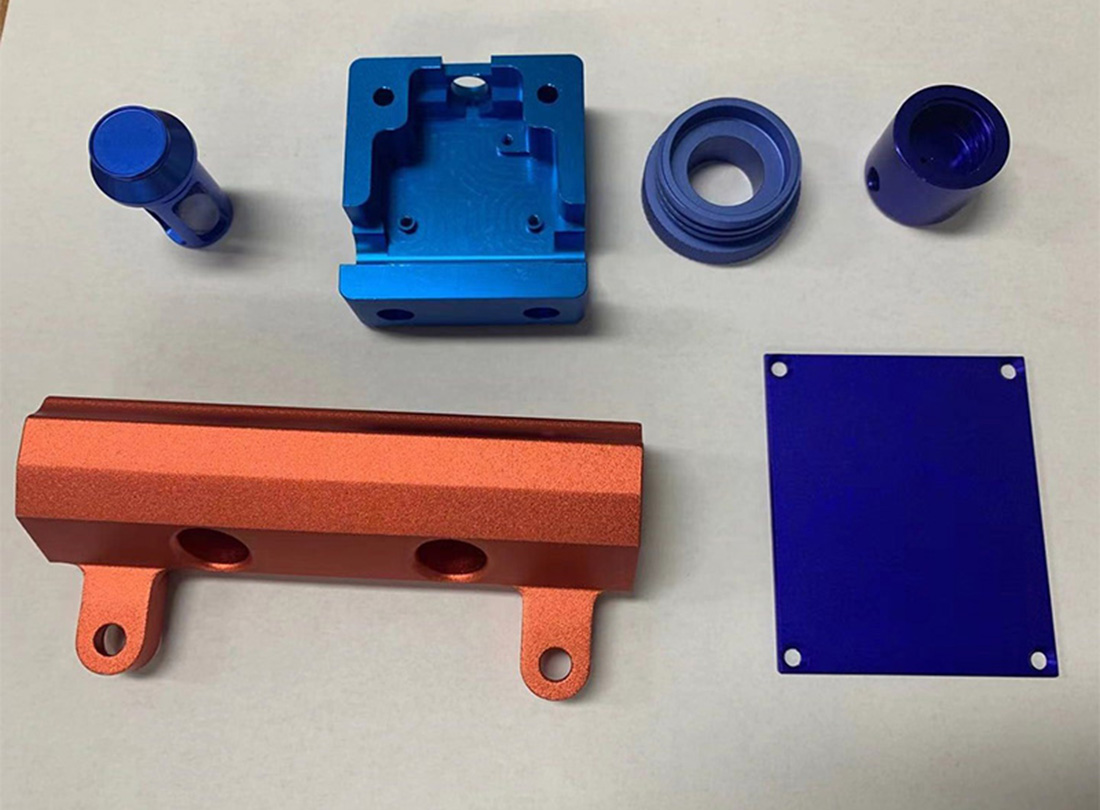

CNC Milling of High Precision Aluminum Machined Parts for the Process Fluid Circulation Industry

Looking for high precision aluminum machined parts for the process fluid circulation industry? We are a factory specializing in CNC milling to meet your needs.

Aluminum 6061 CNC machining Precision Parts for Electronics

Buy high-quality Aluminum 6061 CNC machining precision parts for electronics manufacturing. We are a reliable factory offering superior products at competitive prices.

Shenzhen Die Casting Factory Custom A380 ADC12 Die Cast Part Aluminum Die Casting

Welcome to our Shenzhen Die Casting Factory specializing in custom A380 ADC12 die cast aluminum parts. We are a trusted manufacturer with excellent quality and competitive prices.

Low Volume Production Automative spare parts Urethane Casting

Factory specializing in low volume production of automotive spare parts through Urethane Casting. Trust us for high-quality, custom-made solutions.

Custom Aluminium enclosure sheet metal fabrication

Get top-quality custom aluminium enclosure sheet metal fabrication from our factory. We specialize in precision manufacturing for various industries. Contact us today!

New RCT CNC Machining ABS plastic parts prototype for product development

Get high-quality ABS plastic parts prototypes for product development with our top-notch RCT CNC machining services. We are a leading factory offering expert manufacturing solutions.

- High-Quality Soft Tooling Injection Molding Manufacturer in China

- Reviews

- Related Videos

Introducing our state-of-the-art Soft Tooling Injection Molding, a groundbreaking solution revolutionizing the manufacturing industry. With the ability to produce complex and intricate products with unparalleled precision, our soft tooling injection molding process is set to take your business to new heights. Gone are the days of costly and time-consuming traditional molding methods. Our soft tooling injection molding offers a more efficient and cost-effective alternative that delivers exceptional results. By utilizing molds made from softer materials, we eliminate the need for expensive and time-consuming tooling processes. This not only reduces production costs, but also accelerates the time to market for your products. With our soft tooling injection molding technology, you can now create intricate and delicate designs that were once considered too challenging for traditional molding methods. Our advanced software and cutting-edge machinery allow for unprecedented precision, ensuring that each product is manufactured with extraordinary attention to detail. Not only does soft tooling injection molding enable the production of complex designs, but it also offers superior surface finishes. The molds used in this process allow for the creation of smooth and flawless products, enhancing their appeal and quality. In addition, our soft tooling injection molding process is highly customizable, allowing you to adapt and modify your products quickly and efficiently. This flexibility is particularly beneficial for companies that require frequent design changes or want to test multiple iterations of their products. Experience the next generation of manufacturing with our Soft Tooling Injection Molding. Unleash the power of innovation and stay ahead of the competition by incorporating our state-of-the-art technology into your production processes. Embrace precision, cost-efficiency, and exceptional product quality with our revolutionary solution.

Soft tooling injection molding is a game-changer! I recently acquired a product made using this innovative technique and I couldn't be happier. The quality and precision of the molding are simply outstanding. The soft tooling used in the process allows for more intricate and complex designs, which results in a more aesthetically pleasing end product. Additionally, the soft tooling injection molding technique ensures faster production times and reduced costs, making it an efficient and cost-effective solution. I highly recommend products manufactured using soft tooling injection molding for their superior quality and value.

Soft tooling injection molding provides a cost-effective and efficient solution for manufacturing plastic products. I recently used this technology to produce various prototypes and was impressed with the results. The soft tooling process offered me the flexibility to make design changes on the fly, saving both time and money. The final products had excellent surface finish and dimensional accuracy, making them suitable for various applications. Additionally, the process allowed for faster production cycles compared to traditional injection molding methods. Overall, soft tooling injection molding proved to be a reliable and efficient method for bringing my product ideas to life.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours