- Home

- Plastic Insert Moulding

Leading Plastic Insert Moulding Manufacturer and Exporter from China

Introducing the revolutionary solution for all your plastic molding needs - Plastic Insert Moulding! Shenzhen RCT MFG Co., Ltd. is proud to present this cutting-edge technology that is set to transform the manufacturing industry. As a leading manufacturer, supplier, and factory, we bring you an affordable solution that ensures high-quality production.

Plastic Insert Moulding combines the advantages of injection molding and insert molding techniques, resulting in a seamless integration of different materials and components. Our state-of-the-art machinery and expertise allow us to create precise and durable products, all while keeping costs low.

With Plastic Insert Moulding, you can enhance the strength and functionality of your plastic parts by incorporating inserts seamlessly. This process is ideal for a wide range of industries, including automotive, electronics, and household appliances. Additionally, it provides flexibility in design and reduces assembly time - making your production process more efficient and cost-effective.

Trust Shenzhen RCT MFG Co., Ltd. as your go-to partner for all your plastic insert molding requirements. Contact us today to discuss your project and witness the incredible capabilities of Plastic Insert Moulding firsthand. Improve your product quality, lower costs, and gain a competitive edge in the market with our cutting-edge technology.

Shenzhen RCT MFG CO., LTD

Company News

Related News

Customized High Precision CNC Machining Parts for Aquatic Products Testing Equipmen

Shop our factory's customized high precision CNC machining parts for aquatic products testing equipment. Durable, accurate and reliable. Explore now!

Automotive Plastic Parts injection molding

Find high-quality automotive plastic parts through our injection molding factory. Our precision manufacturing ensures durable and reliable products.

CNC Turning and Milling Delrin/POM parts

Looking for high-quality Delrin/POM parts? Our factory specializes in CNC turning and milling services. Get precision parts with quick turnaround times.

CNC Milling of High Precision Aluminum Machined Parts for the Process Fluid Circulation Industry

Looking for high precision aluminum machined parts for the process fluid circulation industry? We are a factory specializing in CNC milling to meet your needs.

High precision injection molds industrial machine injection mould

Choose our high precision industrial machine injection molds for superior product quality. As a factory, we specialize in offering reliable and efficient injection molding solutions. Contact us now!

Custom Aluminium enclosure sheet metal fabrication

Get top-quality custom aluminium enclosure sheet metal fabrication from our factory. We specialize in precision manufacturing for various industries. Contact us today!

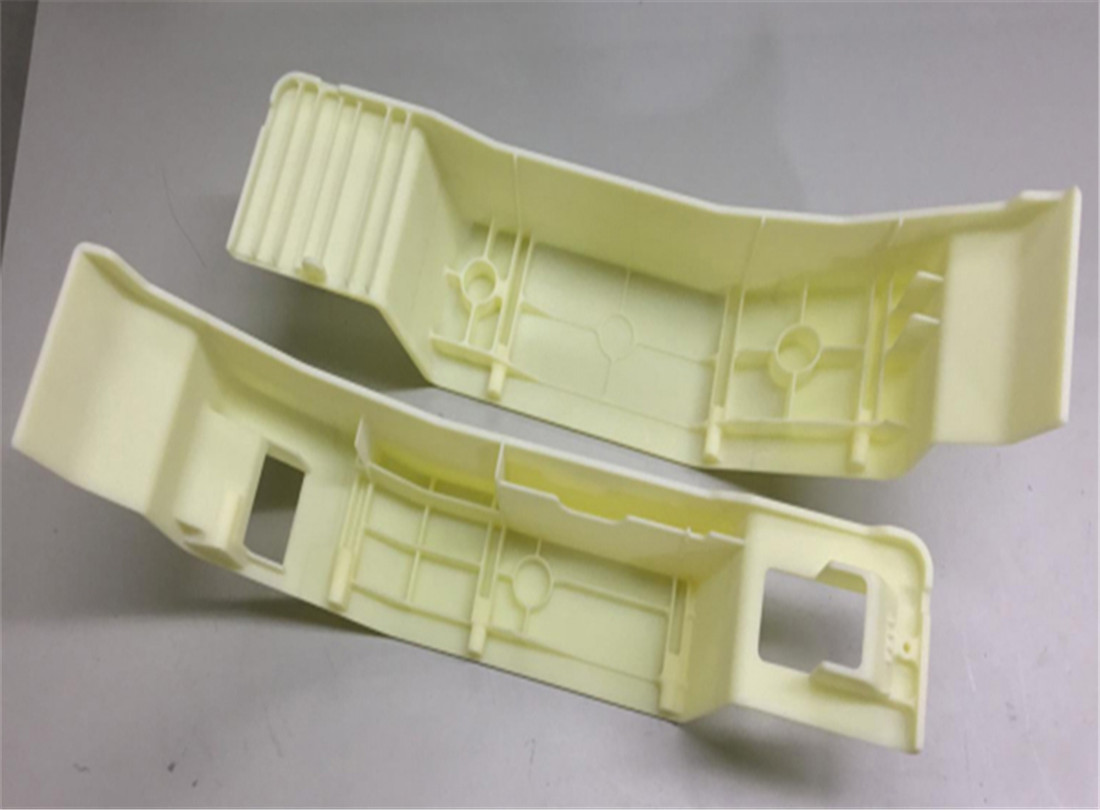

Low Volume Production Automative spare parts Urethane Casting

Factory specializing in low volume production of automotive spare parts through Urethane Casting. Trust us for high-quality, custom-made solutions.

Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts

Shop our high-quality Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts at our factory. Find precise components for efficient machining operations.

CNC Machining of stainless steel housigg for the Gas Compression Equipment Industry

Get top-quality stainless steel housings for the Gas Compression Equipment Industry with our CNC Machining services. We are a trusted factory committed to precision and efficiency.

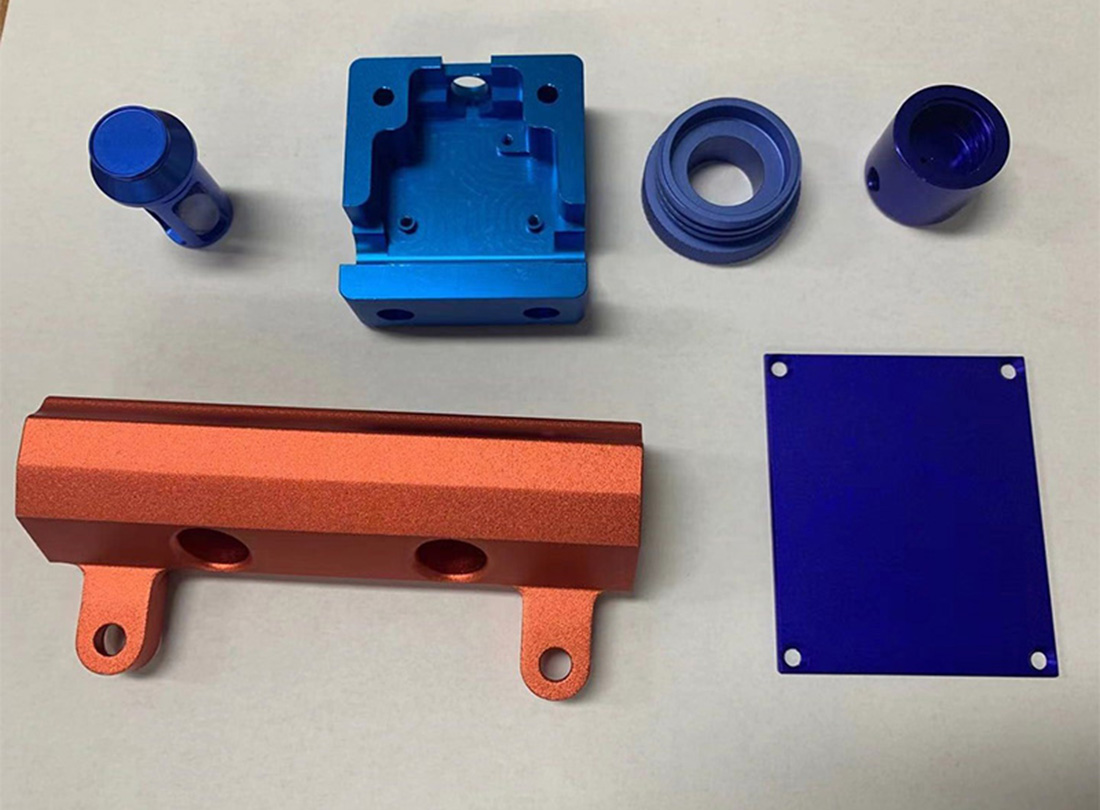

Aluminum 6061 CNC machining Precision Parts for Electronics

Buy high-quality Aluminum 6061 CNC machining precision parts for electronics manufacturing. We are a reliable factory offering superior products at competitive prices.

New RCT CNC Machining ABS plastic parts prototype for product development

Get high-quality ABS plastic parts prototypes for product development with our top-notch RCT CNC machining services. We are a leading factory offering expert manufacturing solutions.

Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts

Experience premium quality with our Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts. As a factory, we assure top-notch craftsmanship and tailored solutions. Shop now!

Precision anodized 7075 Aluminium Machined Wheels for Automative

Shop our line of precision anodized 7075 aluminium machined wheels for the automotive industry. As a factory, we offer quality products at competitive prices.

Shenzhen Die Casting Factory Custom A380 ADC12 Die Cast Part Aluminum Die Casting

Welcome to our Shenzhen Die Casting Factory specializing in custom A380 ADC12 die cast aluminum parts. We are a trusted manufacturer with excellent quality and competitive prices.

Precision biodegradable PLA Bioplastic Injection Molding

Looking for biodegradable PLA injection molding products? Our factory offers precision biodegradable PLA bioplastics for eco-friendly solutions. Contact us now!

- Plastic Insert Moulding Manufacturer - High-Quality Supplier from China

- Reviews

- Related Videos

Introducing our latest innovation in the field of plastic manufacturing - Plastic Insert Moulding. With this cutting-edge technique, we have surpassed the limitations of traditional plastic moulding processes, enabling us to create products with unprecedented precision and versatility. Plastic Insert Moulding is a revolutionary method that combines the strengths of plastic injection moulding and metal insert technology. By seamlessly incorporating metal components within the plastic mould, we can create a wide range of products that boast enhanced durability, strength, and functionality. This process opens up endless possibilities for designing intricate parts and assemblies that were previously unattainable. With our state-of-the-art machinery and skilled team of engineers, we guarantee exceptional quality and seamless integration of metal inserts within the plastic structure. Whether it's intricate electrical connectors, automotive components, or consumer electronics, our Plastic Insert Moulding technique ensures flawless product performance and longevity. One of the key advantages of Plastic Insert Moulding is the reduction in production costs and assembly time. Traditional methods often involve separate processes for manufacturing and assembling metal and plastic components. However, our innovative technique eliminates the need for additional assembly steps, resulting in streamlined production and reduced labor costs. Furthermore, Plastic Insert Moulding allows for lightweight yet robust designs, making it ideal for industries where weight reduction is crucial, such as aerospace and automotive sectors. Our process also offers superior resistance to corrosion and chemical exposure, making it suitable for various applications across diverse industries. In conclusion, our Plastic Insert Moulding technique brings a new level of precision, strength, and efficiency to plastic manufacturing. With our expertise and commitment to excellence, we are confident that this technology will revolutionize the way products are designed and produced. Experience the future of plastic manufacturing with our innovative Plastic Insert Moulding process.

I recently purchased a product that features plastic insert moulding, and I must say I am thoroughly impressed. The plastic insert moulding technology truly enhances the overall functionality and durability of the product. The seamless integration of plastic inserts ensures a strong and secure connection, preventing any potential loose parts or breakage. The quality of the moulding is exceptional, with precise and accurate finish. Additionally, the plastic inserts provide added versatility, allowing for easy customization and modification. Overall, the plastic insert moulding has greatly improved the product's performance and longevity. I highly recommend any product that utilizes this innovative technology.

I recently had the opportunity to try out a plastic insert moulding product, and I must say, I was highly impressed. The quality and durability of the plastic used in this moulding are top-notch. The inserts fit seamlessly and securely, providing a seamless finish that is both aesthetically pleasing and functional. I appreciate the precision and attention to detail in the moulding process. The product exceeded my expectations in terms of strength and longevity, with no signs of wear even after heavy use. If you're looking for a reliable plastic insert moulding solution, I highly recommend giving this product a try.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours