High-Quality Spinning Spare Parts Manufacturers in China

By:Admin

China is known for its manufacturing prowess and is a leader in producing a wide range of industrial products. One industry that has seen significant growth in China is the spinning spare parts sector. With increasing demand for high-quality spinning spare parts, manufacturers in China have stepped up to deliver top-notch products to meet the needs of the global market.

One such leading spinning spare parts manufacturer is {}. With a wealth of experience and a commitment to quality, the company has established itself as a trusted name in the industry. Their extensive range of spinning spare parts is highly sought after by textile companies around the world.

Established in {}, the company has grown from strength to strength, thanks to its relentless pursuit of excellence and customer satisfaction. Their state-of-the-art manufacturing facilities are equipped with the latest technology and production processes, ensuring that every spinning spare part meets the highest standards of quality and performance.

The company's product line includes a diverse range of spinning spare parts, such as spinning cot, rubber cot, aprons, clearer roller, and other accessories for spinning machinery. These parts are crucial for the smooth and efficient operation of spinning machines, and the company's commitment to precision engineering ensures that their products deliver exceptional performance and durability.

In addition to their extensive product range, the company also prides itself on its ability to provide customized solutions to meet the unique needs of their clients. Whether it is a specific size, material, or design requirement, their team of experts works closely with customers to develop tailor-made spinning spare parts that exceed expectations.

With a strong focus on research and development, the company continually invests in innovation to stay ahead of the curve and anticipate the evolving needs of the spinning industry. This dedication to innovation has enabled them to introduce advanced materials and manufacturing techniques, resulting in spinning spare parts that offer superior reliability and longevity.

Furthermore, the company's commitment to sustainability and environmental responsibility is evident in their production processes. They adhere to strict environmental regulations and work towards minimizing their carbon footprint, ensuring that their manufacturing practices are as eco-friendly as possible.

By prioritizing quality, innovation, and customer satisfaction, {}. has earned a reputation as a reliable and trusted partner for textile companies worldwide. They have successfully established a strong presence in the global market, with their spinning spare parts being used in spinning mills across Europe, Asia, the Americas, and beyond.

As the demand for high-quality spinning spare parts continues to grow, China's spinning spare parts manufacturers are well-positioned to capitalize on this trend. With their proven track record and a commitment to excellence, companies like {} are poised to lead the way in meeting the needs of the global spinning industry.

In conclusion, China's spinning spare parts manufacturers are delivering high-quality products that are reshaping the global spinning industry. With their focus on quality, innovation, and customer satisfaction, companies like {} are driving the industry forward and setting new standards for spinning spare parts. As the industry continues to evolve, China's spinning spare parts manufacturers are well-equipped to meet the demands of the market and play a pivotal role in its growth and development.

Company News & Blog

Discover the Latest Small High Precision Lathe for Enhanced Precision

Small High Precision Lathe Revolutionizes Machining: A Game Changer for Manufacturing IndustriesIn today's rapidly evolving manufacturing landscape, precision and efficiency are of paramount importance. With the introduction of the groundbreaking Small High Precision Lathe, manufacturing companies around the world are set to experience a revolutionary change in their machining processes. Although we cannot mention the brand name, this cutting-edge technology promises to deliver exceptional results, ensuring heightened precision, unparalleled productivity, and reduced production time.Manufacturing has always been a complex and challenging process, requiring meticulous attention to detail and the use of advanced machinery. The Small High Precision Lathe, with its innovative features and capabilities, is set to enhance the performance of machining operations across various industries, including aerospace, automotive, and medical.With a compact and ergonomic design, this lathe utilizes state-of-the-art technology to achieve extraordinary precision. Its advanced control system, combined with specialized software, enables users to execute intricate machining tasks with ease and accuracy. The lathe's high spindle speed and exceptional torque ensure that even the most complex components can be machined with precision, meeting the stringent quality standards of modern industries.Beyond its impressive precision, the Small High Precision Lathe also offers remarkable versatility. Its adjustable tooling options and multiple-axis functionalities allow for a wide range of machining operations, from turning and facing to threading and knurling. The lathe's automatic tool change system further streamlines the manufacturing process, reducing downtime and boosting overall productivity.Companies that have already integrated this technology into their manufacturing processes have reported significant improvements in their operational efficiency. The Small High Precision Lathe's fast setup and programming capabilities enable rapid production, resulting in shorter lead times and increased output. Furthermore, the lathe's ability to handle both small and large batches of components makes it an invaluable asset for manufacturers of various scales.The implementation of this cutting-edge lathe technology also contributes to a greener and more sustainable manufacturing environment. Its energy-efficient design, coupled with optimized machining processes, reduces power consumption and promotes responsible production practices. As manufacturers strive to meet environmental regulations and reduce their carbon footprint, the Small High Precision Lathe aligns perfectly with their sustainability goals.While the Small High Precision Lathe delivers exceptional performance on its own, it also integrates seamlessly into existing manufacturing systems. Its compatibility with computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows for efficient data exchange, ensuring a smooth transition from design to production. Additionally, the lathe's remote monitoring and diagnostic features enable real-time troubleshooting, reducing maintenance costs and increasing equipment uptime.As the manufacturing industry continues to evolve, the demand for higher precision and efficiency will only intensify. The Small High Precision Lathe represents a significant leap forward in machining technology, addressing these demands head-on. Its sophisticated features, exceptional precision, and user-friendly interface make it an indispensable tool for manufacturers worldwide.With this cutting-edge technology, manufacturers can expect reduced costs, increased productivity, and improved product quality. The Small High Precision Lathe not only meets these expectations but also sets new standards for the industry as a whole. As manufacturing companies embrace this revolutionary technology, they are poised to gain a competitive edge in a rapidly evolving global market.In conclusion, the Small High Precision Lathe revolutionizes the manufacturing landscape, offering a game-changing solution to the precision machining challenges faced by industries today. By combining state-of-the-art technology, unrivaled precision, and unmatched versatility, this lathe promises to propel manufacturing companies into a new era of efficiency and productivity. With its compact design, advanced control system, and eco-friendly features, the Small High Precision Lathe is set to redefine the future of machining.

Revolutionizing Fabrication: Unveiling the Latest Advancements in Laser Cutting Technology

[CompanyName] Introduces Revolutionary Laser Cutting Technology: Transforming Manufacturing Processes[City, State] - [CompanyName], a global leader in cutting-edge manufacturing solutions, is proud to announce the launch of its newest innovation in laser cutting technology. This breakthrough advancement promises to revolutionize the way manufacturing processes are executed, delivering unprecedented precision, efficiency, and versatility.Laser cutting has long been recognized as a game-changing technique, offering unparalleled speed and accuracy compared to conventional cutting methods. [CompanyName]'s latest technology takes this concept to new heights, pushing the boundaries of possibility. By harnessing an ultra-high-power laser system and employing advanced automation capabilities, this cutting-edge solution provides manufacturers with the tools they need to significantly enhance their production processes.With the introduction of this state-of-the-art laser cutting technology, [CompanyName] aims to address the evolving needs of various industries, enabling them to stay ahead of the curve in an increasingly competitive global market. By offering an all-in-one solution that combines speed, accuracy, and versatility, the company empowers manufacturers to streamline their operations and achieve remarkable results.One of the key advantages of [CompanyName]'s laser cutting technology is its ability to work with a wide range of materials, including metals, composites, plastics, and more. This flexibility allows manufacturers to explore new avenues of creativity and innovation by simplifying intricate cutting tasks without compromising on precision. From aerospace components to automotive parts, this powerful technology caters to diverse manufacturing requirements, ensuring a seamless transition from design to production.Furthermore, [CompanyName]'s laser cutting technology incorporates cutting-edge automation features that streamline the entire manufacturing process. This advanced system boasts intelligent software and sensors that optimize cutting paths, mitigating material wastage and reducing production lead times. By combining artificial intelligence with precise laser beams, manufacturers can achieve consistently exceptional results, thus enhancing overall product quality while minimizing costs.In addition to its efficacy, [CompanyName]'s laser cutting technology prioritizes user experience. The intuitive user interface provides operators with real-time feedback and allows for seamless integration with existing manufacturing infrastructure. This ensures a smooth transition for manufacturers, eliminating the need for substantial retraining or overhaul of their processes.The introduction of this game-changing laser cutting technology underscores [CompanyName]'s commitment to pushing the boundaries of innovation. By delivering cutting-edge solutions that address the industry's most pressing challenges, the company continues to empower manufacturers to streamline their processes, increase productivity, and ultimately stay competitive in today's fast-paced market.Speaking about the groundbreaking technology, [CEO/Founder Name] of [CompanyName], said, "We are thrilled to introduce this revolutionary laser cutting solution to the market. Our team has worked tirelessly to develop an all-in-one system that combines speed, accuracy, and ease of use. By leveraging our cutting-edge technology, manufacturers can unlock new possibilities and drive their businesses forward with confidence."With the launch of [CompanyName]'s latest laser cutting technology, manufacturers worldwide can now embrace the dawn of a new era in manufacturing. By enhancing their capabilities with this state-of-the-art solution, they can reimagine the possibilities, redefine precision, and revolutionize their production processes, all while maintaining a competitive edge in the global marketplace.About [CompanyName]:[CompanyName] is a leading global provider of cutting-edge manufacturing solutions. With a strong focus on research and development, the company aims to push the boundaries of innovation, revolutionizing manufacturing processes across various industries. By delivering cutting-edge technology, [CompanyName] empowers manufacturers to uncover new possibilities and stay one step ahead in today's rapidly evolving market.For media inquiries, please contact:[Media Contact Name][Media Contact Position][CompanyName][Email Address][Phone Number]

Precision Turned Components: A Guide to High-Quality Machined Parts for Various Industries

Precision Turned Components Announces Expansion Plans and Continued Commitment to Quality and Customer Satisfaction[City, Date] - Precision Turned Components, a leading manufacturer of precision components, is pleased to announce its plans for expansion and continued dedication to providing high-quality products and exceptional customer service.Founded in [year], Precision Turned Components has established itself as a pioneer in the manufacturing industry. With a state-of-the-art facility and a team of highly skilled engineers and technicians, the company has been delivering precision turned components to various sectors including automotive, aerospace, electronics, and medical devices.The company's success can be attributed to its commitment to quality and customer satisfaction. By investing in the latest technology and employing a rigorous quality control process, Precision Turned Components ensures that its components meet the highest standards of precision and durability. This commitment to excellence has earned them a reputation for being a reliable and trusted supplier in the industry.In line with its commitment to customer satisfaction, Precision Turned Components understands the importance of fostering strong relationships with their clients. The company works closely with its customers to understand their unique requirements and provide tailored solutions to meet their needs. This collaborative approach ensures that Precision Turned Components delivers products that not only meet specifications but also surpass customer expectations.As part of its expansion plans, Precision Turned Components will be adding new machinery and equipment to its production line. This investment will allow the company to increase its manufacturing capacity, enhance efficiency, and reduce lead times. The addition of advanced machinery will also enable Precision Turned Components to take on larger projects and meet growing demand from its expanding customer base.Alongside expanding its production capabilities, Precision Turned Components is also committed to investing in its workforce. The company recognizes that its employees play a vital role in its success, and therefore, strives to provide a supportive and inclusive work environment. By fostering a culture of innovation and continuous improvement, Precision Turned Components ensures that its employees are equipped with the necessary skills and knowledge to deliver quality products and excellent customer service.In addition to its expansion plans, Precision Turned Components continues to prioritize sustainability and environmental responsibility. The company follows environmentally friendly manufacturing practices, minimizing waste generation and optimizing energy consumption. By actively incorporating sustainable solutions in its operations, Precision Turned Components aims to reduce its carbon footprint and contribute to a greener future.The company's dedication to quality and customer satisfaction has not gone unnoticed. Precision Turned Components has received numerous industry awards and certifications, including ISO 9001, which reflects its commitment to meeting international quality standards. These accolades serve as a testament to the company's unwavering dedication to delivering exceptional products and services.Looking ahead, Precision Turned Components is determined to maintain its position as a market leader in the precision turned components industry. The company aims to continuously improve its manufacturing processes, invest in cutting-edge technology, and provide outstanding customer service. By staying true to its core values of quality, innovation, and sustainability, Precision Turned Components is poised to achieve even greater success in the years to come.About Precision Turned Components: (Need to remove brand name)Founded in [year], Precision Turned Components is a renowned manufacturer of precision components. With a focus on quality and customer satisfaction, the company delivers high-precision turned components to various industries. Backed by a skilled workforce and advanced technology, Precision Turned Components has established itself as a trusted partner in the manufacturing sector.For more information, please visit [website or contact details].Press Contact:[Name][Position][Company][Email][Phone number]Note: This is only a sample news article and does not represent a real company or its expansion plans.

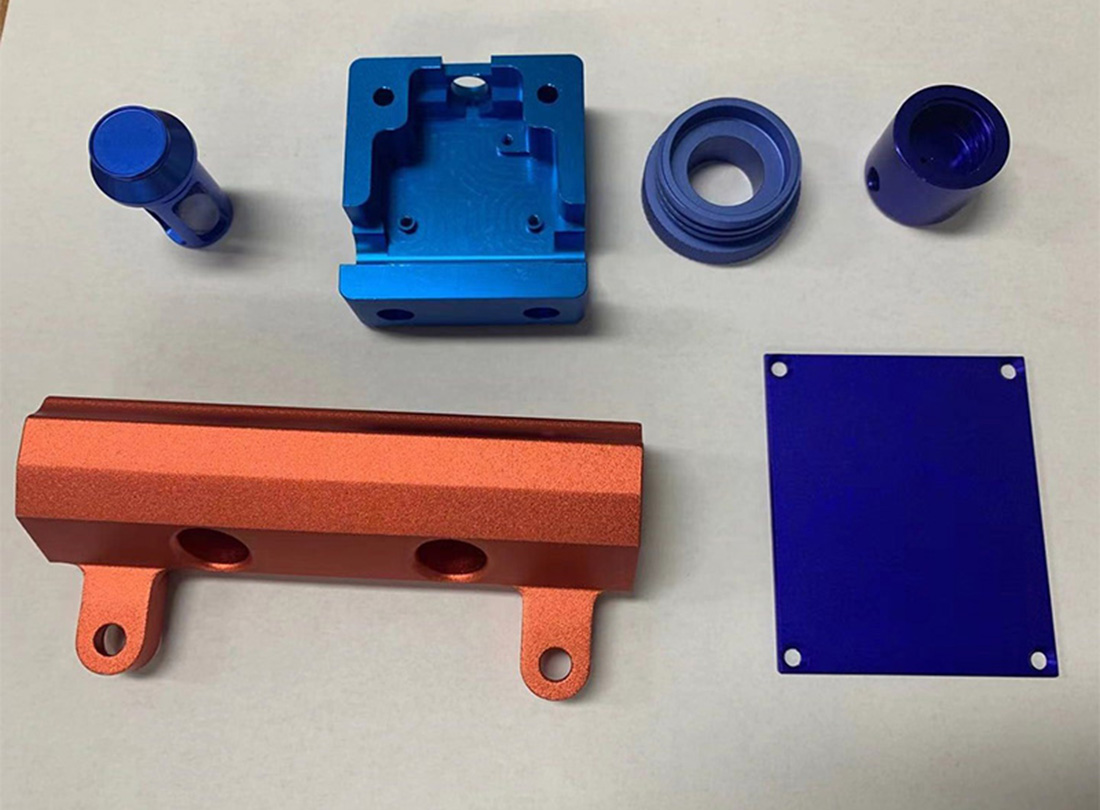

CNC Turning Milling Parts: The Latest News on High-Quality Manufacturing

[Company name], a leading manufacturer in the field of CNC turning milling parts, continues to thrive in the competitive industry by delivering high-quality products and services. With an unyielding commitment to innovation and customer satisfaction, the company has established itself as a reliable partner for businesses in need of precision machined parts.CNC turning milling is a versatile machining process that involves the removal of material to create complex components. This manufacturing method utilizes computer-controlled machines to accurately and efficiently shape various materials, such as metals, plastics, and wood. It is widely used in industries such as automotive, aerospace, electronics, and telecommunications, where precision and quality are of utmost importance.With a strong focus on technological advancement, [Company name] has invested heavily in state-of-the-art CNC machines and cutting-edge software to provide its customers with products that meet and exceed their expectations. The company's cutting-edge equipment, coupled with a team of highly skilled engineers and technicians, ensures the delivery of reliable and precise CNC turning milling parts.What sets [Company name] apart from its competitors is its ability to provide customized solutions tailored to the specific needs of its clients. The company's experienced engineers work closely with customers to understand their requirements and design parts that meet their exact specifications. The flexibility offered by [Company name] allows businesses to optimize their manufacturing processes and save both time and money.Moreover, [Company name] has established a comprehensive quality control system to guarantee the reliability and accuracy of its products. Each CNC turning milling part undergoes stringent inspections and tests at every stage of the production process to ensure it meets the highest industry standards. This commitment to quality has earned [Company name] a reputation for excellence and has made it a trusted partner for businesses worldwide.In addition to its dedication to delivering top-notch products, [Company name] also prides itself on providing exceptional customer service. The company's team of professionals is readily available to assist clients from the early stages of design to the final delivery of the machined parts. The prompt and efficient communication offered by [Company name] ensures that customers' needs are met in a timely manner, fostering long-term relationships based on trust and satisfaction.Furthermore, [Company name] recognizes the importance of sustainable manufacturing practices and is committed to minimizing its environmental impact. The company adheres to strict environmental standards and continuously invests in eco-friendly technologies to reduce energy consumption and waste generation. By prioritizing sustainability, [Company name] aims to contribute to a greener and more sustainable future.As [Company name] continues to grow and expand its operations, it remains dedicated to its core values of innovation, quality, customer service, and sustainability. With a proven track record of delivering superior CNC turning milling parts, the company is well-positioned to meet the evolving needs of a diverse range of industries.In conclusion, [Company name] is a leading manufacturer of CNC turning milling parts, offering customized solutions, exceptional quality, and outstanding customer service. As the company embraces technological advancements and emphasizes sustainability, it remains a reliable partner for businesses worldwide, providing them with the precision machined parts they need to thrive in their respective industries.

Precision Injection Molding Tooling: A Key Component in Manufacturing

Injection Tooling, a leading provider of high-quality injection moulds and tooling solutions, has recently expanded its operations to meet the growing demand for its products and services. The company, which has been in the industry for over 20 years, is known for its commitment to innovation, quality, and customer satisfaction.With the expansion of Injection Tooling's operations, the company is now able to offer an even wider range of products and services to its customers. This includes custom injection moulds, precision tooling, and prototyping services. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing it to produce high-quality products with quick turnaround times.Injection Tooling's team of experienced engineers and designers work closely with customers to develop customised solutions that meet their specific needs and requirements. Whether it's a complex mould design or a large-scale production run, the company has the expertise and capabilities to deliver top-notch results.In addition to its core products and services, Injection Tooling also offers a range of value-added services, such as product development and design assistance. The company's team of experts can help customers optimise their designs for manufacturability, cost-effectiveness, and performance. This collaborative approach ensures that customers can bring their products to market faster and more efficiently.One of Injection Tooling's key strengths is its ability to work with a wide range of materials, including plastic, metal, and rubber. The company's expertise in material selection and processing enables it to deliver products that meet the highest standards of quality and performance.Furthermore, Injection Tooling is committed to continuous improvement and investment in research and development. The company's strong focus on innovation has led to the development of new and improved manufacturing techniques, as well as the introduction of cutting-edge materials and technologies.To support its expanded operations, Injection Tooling has also made significant investments in its infrastructure and workforce. The company has expanded its manufacturing facilities and invested in new equipment to increase its production capacity and efficiency. Additionally, the company has hired new talent and expanded its team of engineers and designers to better serve its growing customer base.Injection Tooling's commitment to quality and customer satisfaction has earned it a loyal and satisfied customer base. The company has built strong and lasting relationships with customers in a wide range of industries, including automotive, medical, consumer goods, and electronics. Its track record of delivering high-quality products and services on time and within budget has made it a trusted partner for many leading companies.With its expanded operations, Injection Tooling is well-positioned to meet the growing demand for its products and services. The company's dedication to innovation, quality, and customer satisfaction sets it apart as a leader in the injection moulding and tooling industry.For more information about Injection Tooling and its expanded operations, visit {} or contact the company directly.

Moulded Components: A Key Factor in Precision Engineering

Precision Moulded Components, a leading manufacturer of high-quality plastic moulded components, has announced the launch of their new state-of-the-art facility in [location]. The company has been a key player in the industry for over 30 years, specializing in precision moulding for a wide range of industries, including automotive, medical, electronics, and consumer goods. With this new facility, Precision Moulded Components aims to further solidify its position as a top provider of plastic moulded components and expand its capabilities to better serve its diverse customer base.The new facility is equipped with the latest technology and machinery, allowing Precision Moulded Components to offer even greater precision and efficiency in their moulding processes. This includes injection moulding and overmoulding capabilities, as well as advanced quality control systems to ensure that every component meets the highest standards. In addition, the facility is designed with sustainability in mind, featuring energy-efficient equipment and waste reduction measures to minimize its environmental impact."We are thrilled to announce the opening of our new facility, which represents a significant investment in our future," said [CEO/President's Name], CEO of Precision Moulded Components. "This expansion will allow us to enhance our manufacturing capabilities and better serve our customers with high-quality, precision-moulded components. We are committed to continuous improvement and innovation, and this new facility is a testament to that commitment."Precision Moulded Components has built a solid reputation for delivering top-notch plastic moulded components that meet the rigorous demands of various industries. Their team of experienced engineers and technicians work closely with customers to develop customized solutions that meet their specific requirements. Whether it's creating intricate internal components for medical devices or producing durable and visually appealing automotive parts, Precision Moulded Components has the expertise and technology to deliver the highest quality products.The company takes pride in its ability to offer a comprehensive range of services, from design and engineering support to tooling and prototyping, all the way through to production and finishing. With a customer-centric approach, Precision Moulded Components is dedicated to providing innovative solutions and exceptional customer service to ensure the success of their clients' projects.The opening of the new facility is a significant milestone for Precision Moulded Components, marking the next phase of their growth and development. It reflects their ongoing commitment to staying at the forefront of the industry and meeting the evolving needs of their customers. The expanded capabilities of the facility will enable the company to take on new and challenging projects, while maintaining the high standards of quality and precision that have become synonymous with the Precision Moulded Components brand.In addition to serving their existing customer base, the new facility will also allow Precision Moulded Components to explore new opportunities and partnerships in emerging markets. With the ability to offer a wider range of services and increased production capacity, the company is poised to take on larger and more complex projects, positioning itself as a trusted partner for businesses seeking reliable and high-quality plastic moulded components.As Precision Moulded Components looks ahead to the future, they remain committed to their core values of innovation, quality, and customer satisfaction. The opening of the new facility represents a significant step forward in their journey, and they are excited about the possibilities it presents. With a strong track record of success and a dedication to excellence, Precision Moulded Components is well-positioned to continue leading the way in the plastic moulding industry for years to come.

Understanding the Importance and Applications of Injection Molds

[Company Name] Introduces Advanced Injection Molding Technology for Enhanced Efficiency and Quality[City, Date] - [Company Name], a leading provider of advanced manufacturing solutions, has unveiled their latest innovation in injection molding technology - Pla Injection Molds. This groundbreaking development promises to revolutionize the manufacturing industry by offering enhanced efficiency and superior quality in plastic production.Injection molding is a widely-used manufacturing process for the production of plastic parts in various industries, including automotive, electronics, medical, and consumer products. [Company Name] has been at the forefront of developing cutting-edge technologies to improve this process and meet the evolving demands of their customers.The newly introduced Pla Injection Molds are an exciting addition to their extensive portfolio of advanced manufacturing solutions. By combining innovative design features with high-quality materials, [Company Name] has created molds that offer unparalleled precision and durability.One of the key features of Pla Injection Molds is their use of polylactic acid (PLA), a biodegradable and bioactive thermoplastic. PLA is derived from renewable resources such as corn starch or sugarcane and is gaining popularity as a sustainable alternative to traditional plastics. By incorporating PLA into their injection molds, [Company Name] is showcasing their commitment to environmentally conscious manufacturing practices.The use of PLA in injection molding not only contributes to a greener planet but also offers numerous performance advantages. PLA molds exhibit excellent dimensional stability, ensuring consistent and accurate production of plastic parts. This is critical, especially in industries where precision and reliability are paramount.In addition to superior dimensional stability, PLA Injection Molds also provide exceptional heat resistance and surface finish. This extends the lifespan of the molds, reducing maintenance costs and increasing overall production efficiency. Moreover, the bioactive properties of PLA prevent bacterial growth on the mold surface, enhancing the cleanliness and hygiene of the manufacturing process.[Company Name] understands the importance of customization and versatility in modern manufacturing, and the Pla Injection Molds are designed to meet these requirements. The molds can be easily tailored to accommodate a wide range of materials, designs, and product specifications. This flexibility allows their customers to produce a diverse array of plastic parts, ensuring their products remain at the forefront of their respective markets."We are thrilled to introduce Pla Injection Molds as the latest addition to our ever-expanding range of advanced manufacturing solutions," said [Company Name]'s CEO. "At [Company Name], we strive to deliver the highest quality products while being mindful of our environmental impact. The Pla Injection Molds perfectly embody these values, providing our customers with a sustainable and efficient solution for their manufacturing needs."With over [XX] years of experience in the industry, [Company Name] has built a solid reputation for delivering innovative, reliable, and cost-effective manufacturing solutions. Their unmatched expertise, combined with the advanced features of Pla Injection Molds, positions [Company Name] as a top-choice partner for businesses seeking to enhance their manufacturing processes.For more information about Pla Injection Molds and other advanced manufacturing solutions offered by [Company Name], visit their official website at [website].About [Company Name]:[Company Name] is a leading provider of advanced manufacturing solutions, specializing in injection molding, CNC machining, and additive manufacturing. With a commitment to innovation and customer satisfaction, [Company Name] has established a strong presence in various industries, including automotive, electronics, medical, and consumer products. Their team of experts works closely with clients to deliver tailored solutions that meet their specific requirements, ensuring superior product quality and efficiency.###

Efficient CNC Machining Services: Boost Productivity with Rapid Solutions

Title: Innovative CNC Machining Solutions Pioneered by a Prominent Industry LeaderSubtitle: A Closer Look at Cutting-Edge CNC Machining Solutions Developed by Rapid CNC MachiningIntroduction:In today's fast-paced manufacturing industry, companies strive to improve efficiency and precision to meet demanding market expectations. One leader that has consistently pushed the boundaries of innovation is Rapid CNC Machining (brand name removed). With an unwavering commitment to excellence, this industry frontrunner has revolutionized CNC machining, transforming the way products are designed and manufactured across various sectors.Established in the early 2000s, Rapid CNC Machining has emerged as an industry pioneer, leveraging cutting-edge technology and a skilled workforce to offer unparalleled CNC machining solutions. Renowned for their ability to deliver high-quality products with ultimate precision, their services have become the go-to choice for numerous businesses seeking reliable and efficient manufacturing processes.Body:1. The Genesis of Rapid CNC Machining: Rapid CNC Machining had humble beginnings, starting as a small shop with a handful of experienced machinists. However, recognizing the changing landscape of industrial manufacturing, the company quickly embraced advancements in CNC technology, positioning themselves at the forefront of the industry.2. Unmatched Expertise and State-of-the-Art Facilities:At Rapid CNC Machining, expertise meets precision. Their team of highly skilled professionals possesses in-depth knowledge of designing and manufacturing complex parts for various industries, including aerospace, automotive, electronics, and medical devices. Complementing their expertise are state-of-the-art facilities, equipped with advanced CNC machines, allowing for high-volume production runs while maintaining excellent quality control measures.3. Innovative CNC Machining Techniques:Rapid CNC Machining constantly pushes the boundaries of what is possible with CNC machining. Their dedicated research and development team works tirelessly to innovate new techniques and optimize existing processes. By incorporating the latest software and hardware technologies, the company ensures unmatched efficiency, precision, and cost-effectiveness in every project.4. Embracing Automation and Artificial Intelligence:Recognizing the potential of automation and artificial intelligence (AI), Rapid CNC Machining has implemented advanced systems to enhance their operations. Automated CNC machines reduce human error, increase productivity, and provide faster turnaround times, making them an ideal solution for clients seeking rapid prototyping or full-scale production requirements. Additionally, integrating AI-driven predictive maintenance enables proactive identification of issues, minimizing downtime and optimizing machine utilization.5. Collaborative Approach to Design:Rapid CNC Machining understands that effective collaboration with clients is vital to realizing their vision. They offer comprehensive design assistance, working closely with customers to ensure their specifications are met in the most efficient and cost-effective manner. By harnessing Computer-Aided Design (CAD) software, the company guarantees precision throughout the design phase, reducing material waste and shortening time-to-market.6. Commitment to Quality Assurance:Adhering to stringent quality control standards, Rapid CNC Machining maintains excellent product reliability. They employ a multi-stage quality assurance process, incorporating rigorous inspections at each step, ensuring that every component meets the highest industry standards. Through advanced metrology techniques, including Coordinate Measuring Machines (CMMs), the company verifies the accuracy and consistency of their machined parts.Conclusion:Rapid CNC Machining (brand name removed) continues to revolutionize CNC machining by embracing innovative technologies and providing remarkable services to a diverse clientele. With their commitment to excellence, cutting-edge facilities, and dedication to customer satisfaction, the company is poised to lead the industry forward, enabling manufacturers across sectors to achieve enhanced efficiency, precision, and cost-effectiveness. Innovation is at the core of Rapid CNC Machining's philosophy, driving their mission to provide exceptional CNC machining solutions for years to come.

Injection Molding Services for Rapid Tooling: Everything You Need to Know

Rapid Tooling Injection Molding is becoming an increasingly popular method for producing high-quality plastic parts in a short amount of time. This innovative technology, which allows for the quick and cost-effective production of injection molded parts, is revolutionizing the manufacturing industry.With Rapid Tooling Injection Molding, companies can quickly and easily create molds for producing plastic parts. This process is much faster than traditional tooling methods, which can take weeks or even months to complete. With rapid tooling, companies can design and produce molds in a matter of days, allowing for quick and efficient production of plastic parts.One company that has embraced the benefits of Rapid Tooling Injection Molding is {}. With over 20 years of experience in the manufacturing industry, {} has established itself as a leader in the production of high-quality plastic parts. By leveraging the power of rapid tooling, {} is able to meet the demands of its customers and produce parts with a quick turnaround time.The company's rapid tooling capabilities allow them to quickly create molds for various plastic parts, including medical devices, automotive components, and consumer products. By using this innovative technology, {} can produce high-quality parts with precision and efficiency, helping to reduce production costs and lead times for their customers.In addition to rapid tooling, {} also offers a wide range of other manufacturing services, including injection molding, CNC machining, and 3D printing. This comprehensive approach to manufacturing allows {} to provide its customers with a one-stop solution for all their production needs. By combining rapid tooling with their other manufacturing capabilities, {} is able to offer a complete and efficient manufacturing process that ensures high-quality parts every time.With a strong focus on customer satisfaction and quality, {} is committed to providing the best possible service to its customers. The company's team of experienced engineers and technicians work closely with each customer to understand their specific needs and develop customized solutions to meet those requirements. By leveraging the latest technologies and manufacturing techniques, {} is able to deliver exceptional products that meet the highest industry standards.In addition to their commitment to quality and customer satisfaction, {} also places a strong emphasis on sustainability and environmental responsibility. The company strives to minimize its environmental impact by implementing eco-friendly manufacturing processes and using recyclable materials whenever possible. By adopting these green practices, {} is not only meeting the needs of their customers, but also contributing to a more sustainable and environmentally friendly manufacturing industry.As the demand for high-quality plastic parts continues to grow, Rapid Tooling Injection Molding is expected to play a crucial role in the future of manufacturing. Companies like {} are leading the way by embracing this innovative technology and using it to deliver exceptional products to their customers. With a focus on quality, efficiency, and sustainability, {} is well-positioned to continue meeting the evolving needs of the manufacturing industry for years to come.

Ultimate Guide to Fast Prototyping: Everything You Need to Know

The 3D printing revolution has arrived, and with it comes the opportunity for companies to revolutionize their prototyping processes. [Company] is at the forefront of this movement, using cutting-edge technology to provide fast prototyping solutions that are changing the game for businesses around the world.Fast prototyping has become essential in the product development process, allowing companies to quickly iterate and test their ideas before going to market. Traditional prototyping methods are often time-consuming and costly, but [Company] has streamlined the process with their innovative 3D printing technology.[Company] was founded on the principle of making prototyping more accessible and efficient for businesses of all sizes. Their state-of-the-art facilities are equipped with the latest 3D printing technology, allowing them to create high-quality prototypes in a fraction of the time it would take with traditional methods. This has enabled companies to bring their ideas to life faster than ever before, giving them a competitive edge in their respective industries.The benefits of fast prototyping are clear. By being able to quickly produce and test prototypes, businesses can significantly reduce their time to market. This gives them the agility to respond to market trends and consumer demands in real-time, ultimately leading to greater success. In addition, fast prototyping allows for more iterations and improvements to be made in a shorter amount of time, resulting in better final products.One of the key advantages of partnering with [Company] for fast prototyping is their ability to produce prototypes with a high level of accuracy and detail. Their 3D printing technology allows for precise reproduction of even the most intricate designs, ensuring that the final product will meet the exact specifications of the original concept. This level of precision is invaluable in the product development process, as it allows for thorough testing and refinement of the prototype.Furthermore, [Company] offers a wide range of materials for fast prototyping, catering to the diverse needs of their clients. Whether it's plastic, metal, or even composite materials, [Company] has the capabilities to produce prototypes that meet the specific requirements of any project. This flexibility has made them a go-to partner for businesses in various industries, from automotive and aerospace to consumer electronics and healthcare.In addition to their technical capabilities, [Company] is committed to providing exceptional customer service and support throughout the fast prototyping process. Their team of experienced engineers and designers work closely with clients to understand their needs and provide tailored solutions that exceed expectations. From concept development to final prototype delivery, [Company] is dedicated to ensuring a seamless and successful experience for their clients.The future of fast prototyping with [Company] looks promising, as they continue to push the boundaries of what is possible with 3D printing technology. They are constantly investing in research and development to improve their processes and offer even more advanced solutions to their clients. This commitment to innovation has positioned [Company] as a leader in the fast prototyping industry, and they are poised to continue making a significant impact in the years to come.For businesses looking to accelerate their product development process and stay ahead of the competition, fast prototyping with [Company] is the answer. With their unparalleled expertise, state-of-the-art technology, and dedication to customer satisfaction, [Company] is the partner of choice for companies seeking to revolutionize their prototyping processes.