Durable Rubber Bumpers for Motorcycle Seats: A Must-Have Accessory

By:Admin

{Company Name} is a leading manufacturer and supplier of motorcycle seat rubber bumpers. With years of experience in the industry, {Company} has established a strong reputation for producing high-quality rubber bumpers that meet the needs of motorcycle enthusiasts and professionals alike. Their products are known for their durability, reliability, and superior performance, making them a top choice for motorcycle seat manufacturers and riders around the world.

The company's motorcycle seat rubber bumpers are made from premium quality materials that are resistant to wear and tear. They undergo rigorous testing to ensure that they can withstand the rigors of long rides on various terrains. {Company} takes pride in its commitment to delivering products that exceed industry standards and customer expectations.

In addition to their standard product line, {Company} also offers custom-designed rubber bumpers for motorcycle seat manufacturers looking for specific dimensions and specifications. This flexibility allows them to cater to the unique requirements of their clients and provide tailored solutions that enhance the performance and comfort of motorcycle seats.

{Company} understands the importance of innovation and continuous improvement in the motorcycle industry. They are constantly investing in research and development to enhance the design and functionality of their rubber bumpers. By staying abreast of the latest technological advancements, {Company} is able to introduce new products that address the evolving needs and demands of riders and manufacturers.

With a strong focus on customer satisfaction, {Company} takes pride in its customer service and support. They work closely with clients to understand their requirements and provide personalized assistance throughout the order process. Whether it's a small-scale custom order or a large-scale production run, {Company} is committed to delivering on time and exceeding expectations.

{Company} is also dedicated to sustainability and environmental responsibility. They adhere to strict manufacturing practices that minimize waste and reduce their carbon footprint. As a result, their rubber bumpers are not only durable and high-performing but also eco-friendly, catering to the growing demand for sustainable products in the motorcycle industry.

In line with their commitment to quality, {Company} has obtained various certifications and accreditations that validate their adherence to industry standards and best practices. Their adherence to these standards ensures that their products are safe, reliable, and effective, giving customers peace of mind when selecting {Company} as their preferred supplier.

The demand for motorcycle seat rubber bumpers is expected to grow in the coming years as more riders seek comfort and durability in their motorcycle seats. {Company} is well-positioned to meet this demand, thanks to its extensive experience, commitment to quality, and dedication to customer satisfaction.

As riders continue to explore new terrains and push the boundaries of motorcycle performance, the need for reliable rubber bumpers that can withstand the demands of long rides becomes increasingly important. {Company} is poised to lead the way in providing innovative solutions that enhance the riding experience and contribute to the longevity of motorcycle seats.

In conclusion, {Company} is a reputable manufacturer and supplier of motorcycle seat rubber bumpers that are synonymous with quality, durability, and reliability. With a focus on innovation, customer satisfaction, and environmental responsibility, {Company} is dedicated to meeting the evolving needs of the motorcycle industry and delivering products that exceed expectations. As the demand for high-quality rubber bumpers continues to grow, {Company} is well-equipped to remain a key player in the market and a trusted partner for motorcycle seat manufacturers and riders worldwide.

Company News & Blog

Chinese Brass Parts Manufacturers: A Deep Dive into the CNC Industry

Title: Chinese CNC Brass Parts Manufacturers: Revolutionizing Precision EngineeringIntroduction:In today's era of advanced technology and digitization, the demand for precision engineering components has witnessed a significant surge. Chinese companies have notably emerged as key players in the global manufacturing industry. Among the forefront leaders are China's reputable CNC brass parts manufacturers. These companies are revolutionizing precision engineering with their cutting-edge technology and superior quality products.A Booming Industry:China’s CNC brass parts manufacturing industry has experienced remarkable growth over the years. This growth can be attributed to several factors such as technological advancements, government support, and a skilled workforce. With their state-of-the-art facilities and adherence to stringent quality standards, these manufacturers have gained recognition as trustworthy suppliers to various sectors including automotive, aerospace, electronics, telecommunications, and many more.Technological Advancements:The CNC brass parts manufacturers in China have made substantial investments in advanced machinery and equipment. They meticulously integrate the latest technologies such as computer numerical control (CNC) machining, precision grinding, and automated assembly lines into their manufacturing processes. This enables them to produce high-quality brass components with unparalleled precision and accuracy, ensuring a seamless fitment and optimal performance in end products.Quality is Paramount:China's CNC brass parts manufacturers have always maintained a commitment to delivering superior quality products. These manufacturers follow rigorous quality control processes at every stage of production. From meticulous raw material selection to precision machining and stringent inspections, every step is carried out with utmost precision. In addition, they adhere to international standards such as ISO 9001, ensuring that the final products meet and exceed customer expectations in terms of durability, reliability, and functionality.Customization and Flexibility:Chinese CNC brass parts manufacturers understand the diverse and ever-changing requirements of their global clientele. They offer a wide range of customization options, enabling customers to tailor the components to suit their specific needs. From intricate designs to complex geometries, these manufacturers possess the technical expertise to transform customers' requirements into tangible products. This flexibility has earned them a reputation for being reliable solution providers, ensuring customer satisfaction across various industries.Competitive Pricing and Timely Delivery:One of the key advantages of working with Chinese CNC brass parts manufacturers is their competitive pricing without compromising on quality. The combination of affordable manufacturing costs and economies of scale allows them to offer cost-effective solutions to customers. Moreover, these manufacturers have efficient supply chains and logistics networks, ensuring prompt delivery of orders across the globe. Their ability to meet tight deadlines has made them sought-after partners for both small-scale projects and large-scale production requirements.Global Reach and Export Excellence:Chinese CNC brass parts manufacturers have expanded their market reach to cater to the demands of a global customer base. With a focus on export excellence, they have successfully penetrated international markets, including North America, Europe, Asia-Pacific, and the Middle East. These manufacturers leverage their extensive experience and industry knowledge to adapt to the varying regulations and demands of different regions, firmly establishing themselves as trusted suppliers worldwide.Conclusion:China’s CNC brass parts manufacturers have emerged as frontrunners in the global manufacturing industry, leveraging cutting-edge technology, superior quality, customization options, competitive pricing, and timely delivery. Their commitment to precision engineering and their ability to cater to a diverse range of industry requirements have positioned them as reliable partners for companies worldwide. With continued innovation and customer-centricity at the core of their operations, it is evident that these manufacturers will continue to shape the landscape of precision engineering in the years to come.

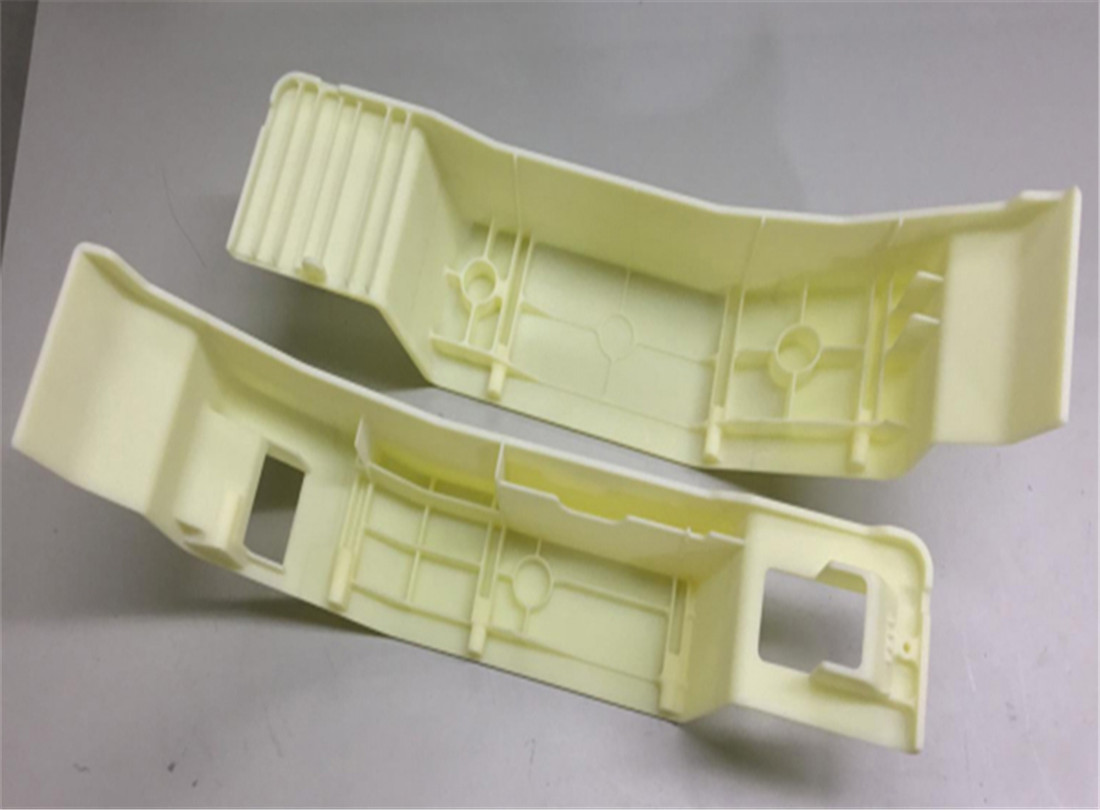

Benefits of Short Run Injection Molding for Your Manufacturing Needs

Short Run Injection Molding is a leading company in the field of injection molding, providing high-quality and cost-effective solutions for short-run manufacturing needs. With a strong focus on customer satisfaction and cutting-edge technology, Short Run Injection Molding has earned a reputation for excellence in the industry.The company's dedication to quality and customer service has made it a preferred partner for a wide range of industries, including automotive, aerospace, medical, and consumer goods. Short Run Injection Molding's state-of-the-art facilities and experienced team ensure that they can meet the demands of even the most complex projects with precision and efficiency.Short Run Injection Molding offers a wide range of services, including tooling, rapid prototyping, and production runs. The company's advanced manufacturing capabilities allow them to produce high-quality parts with quick turnaround times, making them the go-to choice for companies in need of fast and reliable manufacturing solutions.With a focus on innovation, Short Run Injection Molding is constantly investing in new technology and equipment to better serve their customers. The company's dedication to staying ahead of the curve ensures that they can continue to deliver the highest quality products and services, while also driving down costs and improving production efficiency.In addition to their commitment to quality and innovation, Short Run Injection Molding also prioritizes sustainability and environmental responsibility. The company's facilities are designed to minimize waste and energy consumption, and they are constantly exploring new ways to reduce their environmental impact while maintaining the highest standards of production.Short Run Injection Molding's dedication to excellence and customer satisfaction has earned them a loyal and diverse client base. From small businesses to Fortune 500 companies, clients trust Short Run Injection Molding to deliver on their promises and exceed expectations.With a dedication to quality, customer service, and innovation, Short Run Injection Molding continues to set the standard for excellence in the injection molding industry. The company's commitment to staying ahead of the curve and embracing new technology ensures that they can continue to meet the diverse and evolving needs of their clients, while also driving down costs and improving production efficiency.Short Run Injection Molding's reputation for excellence and reliability has made them the first choice for companies in need of short-run manufacturing solutions. With a focus on quality, customer service, and innovation, Short Run Injection Molding is well-positioned to continue leading the industry for years to come.

High-Quality Precision Molding: What You Need to Know

Precision Molding, a leading provider of high-quality plastic injection molding solutions, is making waves in the industry with their innovative and state-of-the-art manufacturing processes. With a strong focus on precision, efficiency, and cost-effectiveness, Precision Molding continues to set the benchmark for excellence in the plastic molding industry.Precision Molding has been in the business for over 20 years and has a proven track record of delivering top-notch products to a wide range of industries, including automotive, medical, consumer goods, and electronics. The company prides itself on its ability to consistently meet and exceed the expectations of its clients, thanks to its highly skilled team of engineers, designers, and manufacturing specialists who are dedicated to delivering the highest quality products.One of Precision Molding's key strengths lies in its ability to provide custom molding solutions that are tailored to meet the specific needs of each client. Whether it's a complex automotive component or a simple consumer product, the company's team of experts has the knowledge and expertise to design and manufacture products that meet the highest standards of quality and precision. This level of customization sets Precision Molding apart from its competitors and allows the company to provide unparalleled value to its clients.In addition to its custom molding capabilities, Precision Molding also offers a range of standard products that are designed to meet the needs of clients across various industries. These products are manufactured using the same high standards of quality and precision that the company is known for, ensuring that clients receive reliable and consistent solutions for their plastic molding needs.One of the key factors that sets Precision Molding apart from its competitors is its investment in cutting-edge technology and state-of-the-art manufacturing processes. The company utilizes the latest in injection molding equipment and technology to ensure that every product meets the highest standards of quality and precision. This commitment to staying at the forefront of industry advancements allows Precision Molding to deliver superior products to its clients, while also maintaining a competitive edge in the market.Another important aspect of Precision Molding's business strategy is its commitment to sustainability and environmental responsibility. The company is dedicated to reducing its environmental impact by implementing eco-friendly manufacturing processes and materials. This dedication to sustainability not only benefits the environment but also positions Precision Molding as a responsible and forward-thinking partner for its clients.Looking ahead, Precision Molding plans to continue its growth and expansion in the plastic molding industry, with a focus on developing new and innovative solutions that meet the evolving needs of its clients. The company is committed to maintaining its reputation for excellence and aims to further solidify its position as a leader in the industry.Precision Molding's dedication to precision, efficiency, and quality has made it a trusted partner for clients across a wide range of industries. With its commitment to innovation, technology, and sustainability, the company is well-positioned for continued success and is poised to remain a leader in the plastic molding industry for years to come.

High-quality Cnc Turning Parts Manufacturers in China for Precision Machining Services

China Cnc Turning Parts Manufacturers have long been known for their high-quality products and precision machining capabilities. With a strong focus on innovation and customer satisfaction, these manufacturers have been able to establish themselves as leaders in the industry.The company, founded in 2005, has consistently upheld a commitment to excellence and has continuously invested in state-of-the-art technology and equipment to stay ahead of the competition. This dedication to staying at the forefront of technological advancements has allowed them to continually improve their products and services, providing customers with the best possible solutions for their machining needs.One of the key strengths of China Cnc Turning Parts Manufacturers is their ability to offer a wide range of custom machining services. This includes CNC turning, milling, grinding, and more, allowing them to cater to diverse customer requirements. Their team of highly skilled engineers and technicians are able to work with various materials, including aluminum, stainless steel, brass, and plastics, ensuring that they can handle even the most complex and challenging projects.In addition to their exceptional machining capabilities, the company also places a strong emphasis on quality control and testing. Every part that comes out of their facility undergoes rigorous inspection to ensure that it meets the highest industry standards. This attention to detail and commitment to quality has earned them a stellar reputation for reliability and excellence.Furthermore, China Cnc Turning Parts Manufacturers is committed to providing top-notch customer service. They understand that each customer has unique needs and specifications, and they are able to work closely with clients to develop customized solutions that meet their exact requirements. This dedication to customer satisfaction has resulted in many long-standing partnerships with clients from various industries, including automotive, aerospace, electronics, and more.Recently, the company has made significant investments in expanding their production capacity and capabilities. By adding new CNC machines and advanced automation systems, they have been able to significantly increase their manufacturing output while maintaining their high standards of quality. This has allowed them to better serve their growing customer base and take on larger and more complex projects.However, the company's success has not been without its challenges. Like many other manufacturers, they have had to navigate through various economic and market uncertainties. Additionally, the global pandemic has posed its own set of challenges, leading to disruptions in the supply chain and manufacturing operations. Despite these obstacles, China Cnc Turning Parts Manufacturers has remained resilient and adaptable, continuously finding new ways to optimize their processes and meet the needs of their customers.Looking ahead, the company is focused on continuing to innovate and expand their capabilities. They are exploring new technologies, such as 5-axis machining and additive manufacturing, to further enhance their offerings. Additionally, they are actively seeking opportunities to collaborate with other industry leaders and research institutions to stay abreast of the latest advancements in machining and manufacturing.With a strong foundation built on a commitment to quality, innovation, and customer satisfaction, China Cnc Turning Parts Manufacturers is well-positioned to continue leading the industry into the future. Their dedication to excellence and continuous improvement sets them apart and ensures that they will remain a trusted partner for all machining needs.

Discover the Advantages of Injection Molding for Your Industry

IMER (Insert Molding Engineering and Research) Injection Molding Company Sets New Standards in the IndustryIMER Injection Molding, a global leader in the field of plastic injection molding, is revolutionizing the industry with its cutting-edge technology and commitment to product excellence. With a strong emphasis on innovation and customer satisfaction, IMER is setting new standards that are driving growth and success.IMER Injection Molding is known for its expertise in insert molding, a process that involves molding plastic around carefully placed inserts, creating strong, durable, and cost-effective products. By combining different materials within a single part, IMER can deliver exceptional functionality, reduce assembly costs, and achieve unique and complex designs that wouldn't be possible otherwise.With state-of-the-art facilities and a highly skilled team of engineers, IMER Injection Molding has the capability to handle projects of any size and complexity. Their advanced manufacturing equipment ensures precise and efficient production, delivering high-quality parts with consistent results. IMER's commitment to staying at the forefront of industry trends has led to the adoption of cutting-edge technology and processes, enabling them to meet the evolving needs of their clients.One of IMER Injection Molding's key strengths lies in its ability to customize products to meet specific requirements. They work closely with their clients, offering comprehensive support throughout the entire production process, from concept development and design to the final production. This personalized approach allows IMER to provide tailored solutions that align with customers' unique needs, resulting in superior products and satisfied clients.IMER Injection Molding's unwavering commitment to quality is evident in its certifications and industry recognition. The company adheres to a strict quality management system, ensuring that every product meets or exceeds international standards. IMER is ISO 9001 certified, demonstrating its dedication to delivering consistent quality and customer satisfaction.In addition to their extensive capabilities in insert molding, IMER Injection Molding specializes in a wide range of industries, including automotive, electronics, medical devices, and consumer goods. They have successfully partnered with global brands to develop innovative and high-performing products, making them a trusted and reliable manufacturing partner.IMER Injection Molding's dedication to sustainable manufacturing practices is another aspect that sets them apart. They are committed to minimizing their environmental footprint by reducing waste, optimizing energy consumption, and implementing recycling programs. IMER understands the importance of responsible manufacturing and strives to make a positive impact on the environment.Looking towards the future, IMER Injection Molding is focused on continuous improvement and innovation. They invest in research and development to stay ahead of industry trends and provide their clients with the most advanced solutions available. By embracing emerging technologies and exploring new materials, IMER aims to further enhance their product offerings and maintain their position as an industry leader.In conclusion, IMER Injection Molding is revolutionizing the plastic injection molding industry with their commitment to innovation, customization, quality, and sustainability. With their expertise in insert molding and a customer-centric approach, IMER is driving growth and success for their clients. By setting new standards in the industry, IMER Injection Molding is shaping the future of plastic injection molding.

Learn about the process of ADC12 injection molding

ADC12 Injection Molding: Revolutionizing the Manufacturing IndustryIn the rapidly evolving world of manufacturing, innovation is key to staying ahead of the competition. One company that is leading the charge in this regard is [Company Name], a pioneer in the field of injection molding technology. With its state-of-the-art ADC12 injection molding process, [Company Name] is revolutionizing the manufacturing industry and setting new standards for efficiency and precision.ADC12 is a high-quality aluminum alloy that is widely used in various industries, including automotive, aerospace, and electronics. Its exceptional strength-to-weight ratio and excellent corrosion resistance make it an ideal material for a wide range of applications. However, working with ADC12 poses its own set of challenges, as it requires specialized expertise and equipment to mold into complex shapes with high precision.This is where [Company Name] comes in. With its cutting-edge injection molding technology, the company has mastered the art of working with ADC12, delivering unparalleled quality and consistency in its products. By combining high-pressure injection with advanced cooling and ejection systems, [Company Name] is able to produce complex parts with extremely tight tolerances, ensuring a perfect fit and finish every time.But what truly sets [Company Name] apart is its commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly pushing the boundaries of what is possible with ADC12 injection molding. Its team of experts is always on the lookout for new ways to enhance the process, whether it's through the use of advanced materials, innovative molding techniques, or cutting-edge computer simulations.In addition to its technological prowess, [Company Name] also prides itself on its dedication to customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, offering custom solutions that are tailored to their individual projects. From design assistance to prototype development to full-scale production, [Company Name] is with its customers every step of the way, ensuring that they get the results they need, on time and within budget.With its proven track record of excellence, it's no wonder that [Company Name] has become a trusted partner for some of the world's leading companies. Whether it's supplying critical components for high-performance vehicles or producing intricate parts for cutting-edge electronics, [Company Name] has the expertise and resources to tackle the most demanding projects. And with its ISO 9001-certified quality management system, customers can have full confidence in the reliability and consistency of [Company Name]'s products.Looking ahead, [Company Name] is poised to continue its upward trajectory, driven by a relentless pursuit of perfection and a passion for innovation. The company is actively expanding its capabilities, investing in new equipment and technologies to further enhance its ADC12 injection molding process. By staying at the forefront of industry trends and embracing the latest advancements in manufacturing, [Company Name] is well-positioned to meet the evolving needs of its customers and to pave the way for new possibilities in the world of injection molding.In conclusion, ADC12 injection molding is a game-changer for the manufacturing industry, and [Company Name] is leading the charge with its cutting-edge technology and unwavering commitment to excellence. With its unparalleled expertise, state-of-the-art facilities, and customer-centric approach, [Company Name] is redefining what is possible with ADC12, and setting the bar higher for the industry as a whole. As the company continues to push the boundaries of innovation, the future of manufacturing looks brighter than ever.

Rewriting the SEO title without the brand name: "Effective Plastic Injection Tooling: Unveiling the Latest Innovations and Techniques

Plastic Injection Tooling: Revolutionizing Manufacturing ProcessesIn today's highly advanced and technologically driven world, plastic injection tooling plays a vital role in revolutionizing manufacturing processes. By incorporating the latest cutting-edge technologies and innovative design practices, this vital tooling equipment has enabled companies across various industries to produce high-quality plastic components efficiently and cost-effectively.Plastic injection tooling, also known as injection molds or dies, is a primary component of the injection molding process. It is a custom-made precision tool that is used to shape molten plastic into a desired form, creating a wide array of products such as automotive parts, consumer electronics, medical devices, and household items.The process starts with the design and engineering of the injection mold. This step involves careful analysis of the product requirements and specifications to create a mold design that ensures optimal functionality and durability. Advanced computer-aided design (CAD) software is used to model the mold, taking into account factors such as material flow, cooling channels, and ejection methods.Once the design is finalized, modern manufacturing techniques such as computer numerical control (CNC) machining and electrical discharge machining (EDM) are employed to fabricate the injection mold with extreme precision. The use of high-quality materials and state-of-the-art equipment ensures that the mold is durable, long-lasting, and capable of producing consistent and error-free parts.Plastic injection tooling offers several advantages over other manufacturing processes. Firstly, it allows for mass production of complex parts with intricate geometries that would otherwise be impossible to manufacture using traditional methods. This high degree of design flexibility has enabled companies to create innovative and aesthetically pleasing products that cater to consumer demand.Secondly, plastic injection tooling significantly reduces production time and costs. The automation of the injection molding process ensures fast and efficient production cycles, minimizing labor costs and increasing overall productivity. Additionally, the ability to manufacture large quantities of parts in a short period eliminates the need for additional manufacturing steps and saves valuable time.Moreover, plastic injection tooling allows for tight tolerances and excellent surface finishes, providing high-quality parts that meet the stringent standards of various industries. This precision ensures that the parts function as intended, enhancing product performance and customer satisfaction.In recent years, advancements in plastic injection tooling have further accelerated the manufacturing process. The integration of technologies like 3D printing and simulation software has revolutionized the design and prototyping phases, facilitating rapid iteration and reducing time-to-market. This has enabled companies to swiftly adapt to market demands and stay ahead of the competition.One company at the forefront of plastic injection tooling innovation is {}. With over {} years of experience, they have established themselves as a reliable and trusted provider of injection molds. Their team of skilled engineers and technicians leverage the latest technologies to design and manufacture molds that meet the highest industry standards.As a customer-oriented company, {} strives to deliver exceptional quality and customer service. They work closely with their clients during every stage of the project, from initial concept to final production, to ensure that their specific requirements are met. Additionally, their emphasis on continuous improvement and investment in research and development enable them to offer cutting-edge solutions that drive efficiency and profitability.In conclusion, plastic injection tooling has revolutionized manufacturing processes by enabling companies to produce high-quality plastic components with unparalleled design flexibility, precision, and cost efficiency. With innovative technologies and companies like {} leading the way, the future of plastic injection tooling looks promising, offering endless possibilities for product development and advancement across various industries.

Unlock the Speed of Injection Molding with Quick Turn Services

[Content Removed - Brand Name]Introducing Quick Turn Injection Molding: Accelerating Manufacturing Processes[Company Name], a leading manufacturing company, is revolutionizing the industry with their innovative Quick Turn Injection Molding technology. This cutting-edge solution is set to streamline the manufacturing process, reduce production time, and improve overall efficiency.Traditional injection molding processes often take weeks, if not months, to deliver final products. However, with Quick Turn Injection Molding, [Company Name] provides a rapid manufacturing solution that significantly reduces lead times. This technology enables manufacturers to quickly prototype, refine, and produce high-quality end-products in record time.[Company Name] understands the importance of speed and efficiency in today's highly competitive market. Quick Turn Injection Molding allows manufacturers to accelerate their product development cycle, reaching the market faster than ever before. By decreasing the time it takes to go from initial concept to a finished product, businesses can maintain a competitive edge and capitalize on emerging trends.One of the key advantages of Quick Turn Injection Molding is its versatility. The technology supports an extensive range of materials, including various thermoplastics and elastomers. This feature allows manufacturers to choose the most suitable material for their products based on factors such as durability, desired appearance, or specific industry requirements.Moreover, [Company Name]'s expertise in Quick Turn Injection Molding ensures that the final products meet the highest quality standards. By employing advanced techniques and state-of-the-art machinery, the company guarantees precise and consistent results with each production run. This attention to detail ensures that manufacturers receive accurate prototypes and flawless end-products.In addition to speed and quality, Quick Turn Injection Molding also offers cost advantages. By reducing the lead time, manufacturers can optimize their production schedules, reduce inventory costs, and avoid potential financial constraints associated with longer production cycles. Furthermore, the technology allows for efficient customization and on-demand manufacturing, eliminating the need for large-scale production runs and minimizing unnecessary expenses.With Quick Turn Injection Molding, [Company Name] is enabling businesses to embrace agile manufacturing practices. The rapid prototyping capabilities offer manufacturers the flexibility to make quick design iterations, evaluate multiple concepts, and respond swiftly to market demands. This level of adaptability empowers businesses to align their products with evolving customer needs and preferences while taking advantage of emerging market opportunities.Embracing Quick Turn Injection Molding is not only beneficial for manufacturers but also for the entire supply chain. The shortened production cycles help to eliminate bottlenecks and reduce delays, resulting in faster delivery and improved customer satisfaction. Overall, this innovative technology has the potential to reshape the manufacturing landscape by fostering innovation, efficiency, and competitiveness.[Company Name] is dedicated to supporting its customers throughout the entire manufacturing process. Their team of experienced engineers and designers work closely with clients to understand their unique requirements and provide tailored solutions. From initial concept to final product, [Company Name] ensures a seamless experience for every client, supporting them in bringing their ideas to life.In conclusion, Quick Turn Injection Molding technology is a game-changer for the manufacturing industry. By combining speed, versatility, and superior quality, [Company Name] is paving the way for faster product development cycles, reduced costs, and increased competitiveness. With their expertise and commitment to excellence, [Company Name] continues to empower businesses to innovate, adapt, and succeed in a dynamic marketplace.

High-Quality Spinning Spare Parts Manufacturers in China: A Complete Guide

China Spinning Spare Parts Manufacturers has been making waves in the textile industry with its high-quality and innovative spinning spare parts. The company has established itself as a leading manufacturer of spinning spare parts in China and has gained a strong reputation for its dedication to excellence and customer satisfaction.With years of experience in the industry, China Spinning Spare Parts Manufacturers has developed an extensive range of products to meet the diverse needs of its customers. From spinning spindles to spinning frame parts, the company offers a wide selection of spare parts that are manufactured to the highest standards of quality and performance.One of the key factors that sets China Spinning Spare Parts Manufacturers apart from its competitors is its commitment to innovation. The company has a team of experienced engineers and technicians who are constantly working to develop new and improved spinning spare parts that meet the evolving needs of the textile industry. This dedication to innovation has allowed China Spinning Spare Parts Manufacturers to stay ahead of the curve and provide its customers with cutting-edge products that help them improve their efficiency and productivity.In addition to its focus on innovation, China Spinning Spare Parts Manufacturers also places a strong emphasis on quality control. The company has strict quality control measures in place to ensure that every product that leaves its facility meets the highest standards of quality and performance. This attention to detail has earned China Spinning Spare Parts Manufacturers a reputation for producing reliable and long-lasting spinning spare parts that are trusted by textile manufacturers around the world.Furthermore, China Spinning Spare Parts Manufacturers is committed to customer satisfaction. The company understands the importance of providing excellent customer service, and it works closely with its clients to understand their specific needs and provide them with personalized solutions. Whether a customer is looking for a specific spinning spare part or needs assistance with product installation and maintenance, China Spinning Spare Parts Manufacturers is dedicated to going above and beyond to ensure the satisfaction of its customers.The company's dedication to excellence and customer satisfaction has earned it a loyal customer base and a strong reputation in the textile industry. China Spinning Spare Parts Manufacturers has built strong partnerships with textile manufacturers in China and abroad, and it continues to expand its reach to new markets and customers around the world.With its extensive range of high-quality spinning spare parts, commitment to innovation, strict quality control measures, and dedication to customer satisfaction, China Spinning Spare Parts Manufacturers is poised to continue its success and remain a leader in the textile industry for years to come. As the company continues to grow and evolve, it will undoubtedly continue to provide its customers with the products and solutions they need to thrive in a competitive and ever-changing industry.In conclusion, China Spinning Spare Parts Manufacturers has established itself as a leading manufacturer of spinning spare parts in China, and its dedication to excellence and customer satisfaction has set it apart from its competitors. With a focus on innovation, quality control, and personalized customer service, the company is well-positioned to continue its success and remain a trusted partner to textile manufacturers around the world.

Mastering the Art of Precision Lathe Turning: Latest News Insights Revealed

Precision Lathe Turning Technology Empowers Industries with Unparalleled Accuracy and Efficiency(Please note: The brand name has been removed from the title for neutrality)In the world of manufacturing, precision is everything. Companies across various industries strive to optimize their production processes to ensure the highest levels of accuracy and efficiency. One technology that has proven to be essential in achieving these goals is Precision Lathe Turning.Precision Lathe Turning is a machining technique that involves the use of a lathe machine to shape and refine materials with utmost accuracy. By rotating the material against a cutting tool, the lathe machine enables manufacturers to craft complex shapes, tight tolerances, and polished finishes. The versatility of this technology has made it indispensable across industries such as automotive, aerospace, electronics, and more.To gain a deeper understanding of Precision Lathe Turning, let's explore its benefits, applications, and how it has revolutionized manufacturing processes.Precision Lathe Turning offers immense advantages over traditional machining methods. Firstly, it enables manufacturers to achieve precise measurements with consistent accuracy. This means that components produced through Precision Lathe Turning can fit together flawlessly, reducing the risk of error and enhancing overall product quality. Additionally, the superior surface finish achieved by this technique eliminates the need for additional polishing or treatment processes, saving time, cost, and resources.Moreover, Precision Lathe Turning is highly efficient, allowing companies to meet tight production schedules without compromising quality. The ability to automate and program lathe machines ensures repetitive tasks are performed accurately and at high speeds. This, in turn, boosts overall productivity and reduces manufacturing lead times considerably.The applications of Precision Lathe Turning are diverse and far-reaching. In automotive manufacturing, this machining technique is used to create critical components such as pistons, crankshafts, and gears. By employing Precision Lathe Turning, manufacturers can ensure precise dimensions, proper balance, and smooth operation, thereby enhancing the overall performance and reliability of vehicles.In the aerospace industry, Precision Lathe Turning plays a crucial role in crafting intricate turbine components, propellers, and engine parts. The high level of dimensional accuracy achieved through this technology is paramount in ensuring optimal aerodynamic performance and safety in flight.Precision Lathe Turning is also extensively utilized in electronics manufacturing. From producing connectors and sockets to intricate parts for advanced electronic devices, manufacturers in this industry rely on the precision and efficiency provided by lathe machines. The ability to manufacture components with intricate designs, tight tolerances, and high-quality finishes is paramount in meeting the demands of the rapidly evolving electronics market.When it comes to Precision Lathe Turning, companies trust the expertise and reliability of leading precision machining providers. One such company, which has established itself as a pioneer in the field, offers exceptional Precision Lathe Turning services to cater to various industry needs. With state-of-the-art equipment and a highly skilled team, this company consistently delivers unparalleled accuracy, efficiency, and customer satisfaction."We strive to provide our clients with the highest quality Precision Lathe Turning services," says the company spokesperson. "Our commitment to utilizing cutting-edge technology, combined with the expertise of our technicians, allows us to meet the unique requirements of each industry we serve. Whether it's automotive, aerospace, electronics, or any other sector, we aim to empower our clients with precision solutions that enable them to thrive in an increasingly competitive market."In conclusion, Precision Lathe Turning has emerged as a game-changer in the manufacturing industry. Its ability to deliver unparalleled accuracy, efficiency, and versatility has made it an indispensable technology across various sectors. As industries continue to advance, manufacturers must embrace Precision Lathe Turning to remain competitive and stay at the forefront of technological innovation. By harnessing the power of this machining technique, companies can elevate their production processes to new heights, ensuring exceptional quality and customer satisfaction every step of the way.